Thanks for the quick responses! I think we have

the basis for a good, educational discussion and hopefully can carry these

forward to a final set of recommendations. With regard to specific

comments:

Hamid wrote: I think the importance of good

workmanship and proper component selection has not been emphasized enough.

I agree entirely. If you put a $4 Radio Shack toggle

switch in to control a critical system, I think you are playing Russian Roulette.

I recall years ago talking to the shop manager at Lancair Avionics (several shop managers ago).

He had tested many rocker switches, and found most

to be not especially reliable.

Can some of you contribute suggestions on what constitutes a

satisfactory component (like the diode mentioned) for various applications?

Can we compile some suggested work standards for the electrical work in our

airplanes? Many standards exist. It would be

great if they could be distilled by those who work with these standards every

day, and assembled in one place for all of us to reference. Regarding the

question of panel switches, I followed Brent Regan’s lead and put in high quality,

environmentally sealed Honeywell/Microswitch sealed toggle switches. (Eaton

makes a similar line.) These are qualified for use in tanks, Humvees and

other vehicles operating in awful environments. Not cheap, but since

switches represent potential single point failures, I believe their selection

is wise.

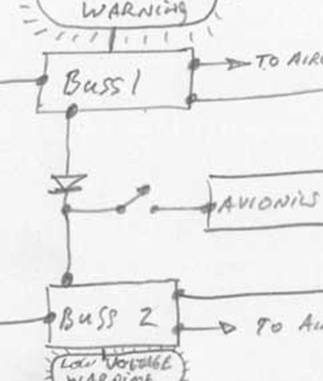

Hamid also wrote: Looking over your design, I see

one issue: Will the bus 1 to bus 2 diode keep you from reliably getting the low

voltage warning on bus 2?

Beats me, Hamid, I am just a dumb mechanical engineer.

What do your think, and what would you recommend?

Also, to all reviewing my dodgy sketch, you missed that I forgot to

insert the second diode to feed the avionics bus. See the missing diode

now? (My sketching workmanship standards need improvement.)

John wrote: If one uses the B&C voltage

regulators and the circuit therein to power a caution lamp, it would be

adequate to detect a pending low voltage on a buss. No? I'm not sure how the

Chelton gauges are wired, but they should provide voltage readouts from the two

busses, and probably current as well.

Sounds right to me, John, but I am not specifically familiar

with the B and C hardware and not qualified to evaluate it. I can tell

you what I have done. Based on recommendations received, when I upgraded

my early generation (circa 1999) Chelton hardware I tossed the EAU (engine

monitoring unit) and purchased an Electronics International MVP-50. Among

many other things, I have it configured

to monitor electrical load on both the A and B buss (amperes being drawn by the

aircraft in each system) and voltage levels on each buss. The unit

permits one to set trip levels for alarm, and the alarm is both audible and

visible. As long as the cross feed is not engaged, failure of one

alternator should result in low bus voltage and an alarm. But because I

have one little alternator and one big one, the subsequent response strategy

and load shedding depends on which alternator continues to operate. Once

I understand the fault and shed load, I will head for the ground. Note

that Columbia (and probably Cirrus) have two big

alternators.

John also wrote: One philosophical slant for me is

the use of the essential and avionics busses. They complicate the design and

increase the parts count, with their consequent effect on reliability. With a

reliable crossfeed contactor, you can have the same benefits of both of these

busses. The only thing for the pilot would be to manually reduce the electrical

load as required.

I understand your point, but suggest you consider the

following: What about the case of a cross feed contactor (or its switch or its

wiring to and from the switch or contactor attachments points….)

failing? A single point failure and poof- benefits evaporate. Would

you test the cross feed system at each run up to make sure it works? Even

if it does, a subsequent single point failure in the cross feed hardware, and

you have a problem. Consider also a bad short on one buss that takes it

off line. If you hit the cross feed as your first response you might

bring down the second buss as it leaps into the short circuit. Now the

airplane is dark and everything turns off. Oops. Consider this and

other possible failure modes. A complete “failure modes and effects

analysis” (FMEA) considers literally hundreds of combinations and

permutations of this type. Today it is done for FAR 23

certification. Most of us are not capable of doing such a thorough

job. So we should steal good designs from others if we are confident that

they are “better.”

Scott (and via Scott, Klaus) wrote lots of good stuff

including:

- It was reported

on the Lancair Mail List that Light Speed Engineering is no longer shipping/selling

dual ignition systems and only recommends a single system with a mag

backup because of too many experimental aircraft's unreliable electrical systems. To which Klaus

replied: There was a concern for a

while when we had a few sensor failures on the Continentals used on

Lancairs. The engine builder would set up the proper clearance per our

instructions, test run the engine and deliver it. The proud owner would

then install his own baffling between the case and our mounting bracket.

This would reduce the clearance to the point that the sensors could get

damaged.

I made an assumption as

to the cause of the caution (faulty electrical systems). I have to remind

myself how to spell ASS-U-ME. L

I am pleased that the problem has been isolated and corrected. Apparently

my Continental engine was caught in this cautionary period, and the engine

builder put on one mag and one Lightspeed ignition system. Now my engine

is making its way across the Pacific this way. Alas.

- Elder* Cessna

aircraft (I have some experience) use crappy components and connectors and

are frequently full of architecture and design shortcuts used to save

MONEY, not lives.

Absolutely correct, in

my direct experience. I could not believe the crap that Cessna put in my

brand new TR-182 when I bought it new in 1979. That includes switches,

circuit breakers, and other important electrical components.

- Sorry, I cannot

trust that the FAA knows any better

than an experimental aircraft builder that actually built his/her airplane

and studied available information on how-to-do-it.

Ah, Scott, you are being

cynical, but your cynicism is not misplaced. I agree that a builder familiar

with the topic should be able to build an electrical system equal to or better

than that specified by the FAA. But I am a little familiar with some

current certification processes via the CAA (Australia’s

equivalent to the FAA). CAA follows FAA on FAR 23, and in my recent

discussions with CAA I learned about requirements that manufacturers present a

quantitative safety case that subjects system designs to thorough data validation

and mathematical analysis. This is a post “elder Cessna” phenomenon,

and probably more than we as homebuilders can hope to achieve.

I merely suggest that FAA-approved

designs for MODERN aircraft provide a good STARTING point. If you are

limiting yourself to day VFR, your standards can (should) be relaxed. But

since some of us are apparently flying night, IFR, single pilot, over the

mountains at high altitude, I suggest we get the best input we can

obtain. Hence my call for an exchange of thoughts and preparation of some

recommendations and example workmanship standards that can be used by all to

improve the quality of our projects.

- One of the things

the builder cannot fix with hardware is the loss of life from serious

lapses of judgment, training and knowledge in the other

single-point failure, the pilot.

Excellent point. We should ever lose sight of the fact that

most of the time pilots kill pilots, not airplanes.

Let the adventure continue!

Fred Moreno

AKA Captain Tuna, Chicken of the Skies