|

|

I'm spinning this off from the fast-taxi-testing thread.

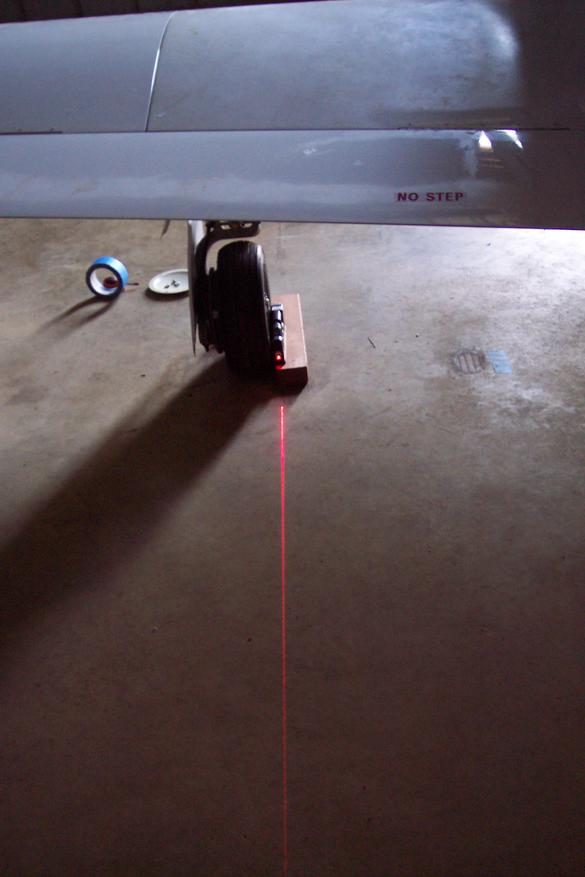

This morning I checked the alignment of my main landing gear using a

$10 Laser

Level in a darkened hanger. This unit doesn't just shoot a point

of light, but has a fan-shaped pattern which leaves a line along

the floor or the bottom of the aircraft and up a wall. I just set

the level on a piece of 2x4, snugged it up against the tire on each

side, shot a line 10' back to the tail area from both tires, and

made a mark on a piece of blue tape stuck to the hangar floor on

either side. Then I used a carpenter's square and a level to drop a

line from the center of the tail and made another mark on the floor.

(A plumb bob would work better but I didn't have one handy.)

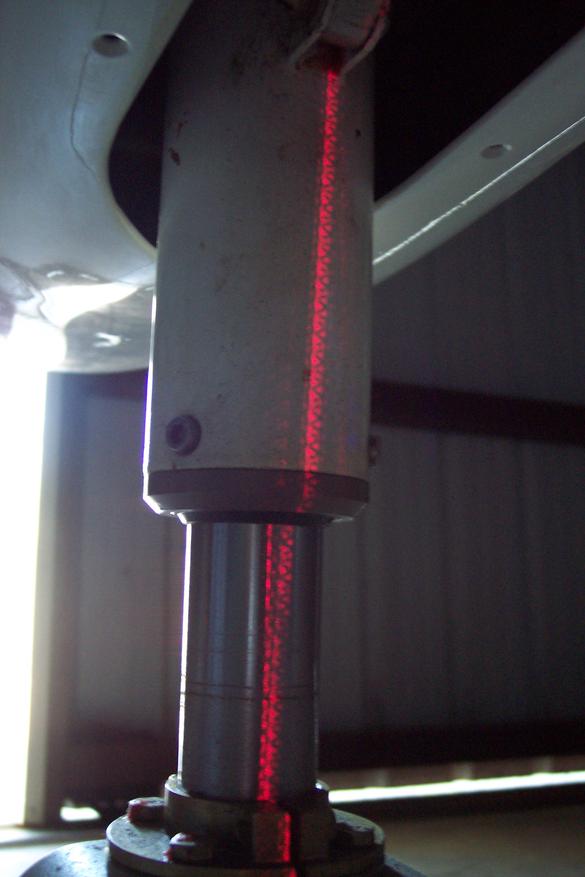

Then I moved the laser level back to the floor under the tail and

shot a line forward from the centerline back there to the

over-center link on the nose gear, and also to a mark on the floor

midway between the two tires. (At this step it was necessary to

insure that the laser level was also level from side-to-side so the

fan pattern would be vertical.) The whole job took about an hour and

was was much easier than using a long box beam to measure the

angles. With a little care, I believe the method can be very

accurate. The only downside to this cheap laser level is that it

uses three expensive button batteries that don't last too long. A

set of fresh batteries cost me more than the unit itself - about $12

at Radio Shack.

|

|