|

|

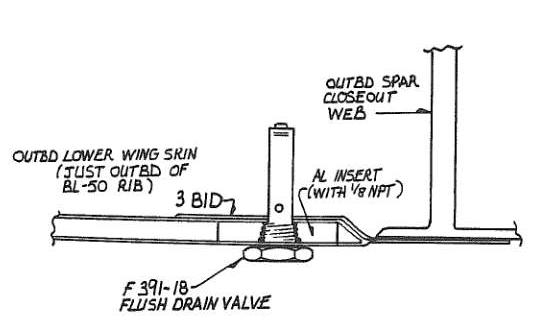

When building my 235 wing tanks, I was concerned that the drain

valve wasn't located at the lowest part of the tank, possibly

allowing water to accumulate next to the BL-51(?) rib. Here is what

the instruction manual showed:

I chose to mount the flush drain exactly in the lowest

portion of the bottom wing skin where there was no foam core.

I drilled a hole at the lowest point then used structural adhesive

to glue the aluminum hard point onto the outside of the

bottom wing skin so that the drain holes in the quick-drain were

peeking just above the interior of the tank sealant. Afterwords, I

fiberglassed over the hard point, which I had previously rounded and

beveled. When it came time to finish the aircraft, I used micro to

build up an aerodynamic "blister" to cover the hard point and quick

drain. I probably lost a couple of Potential Knots of airspeed by

sticking the drain out into the wind, but I won't have to worry so

much about un-drainable water in the wing tanks.

Speaking of water, we had a recent weather change here in NC from

40-ish to warm and humid and rainy. The entire aircraft was

sweating in the hangar - not just the engine but the fiberglass

airframe as well. I'd never seen anything like that and I have to

assume that under such conditions, moisture could also build up inside

the fuel tanks. It's something to think about. Here's what my

"blister" looks like, and you can actually see the condensation in

the photo:

|

|