When my O-290-D2 was on the engine stand last month, a large puddle

of engine oil gradually appeared underneath. The front crankshaft

oil seal had to be the source of the leak so I resolved to have it

replaced before my first flight. I've been bugging the local A&E

to R-and-R the seal, but he's been too busy or something. So today I

removed the old seal myself with a hook and ordered a replacement

seal and some Pliobond 20 at Aircraft Spruce. Here are a couple

photos of what I found in there. Now keep in mind that this engine

was built up by Don George of Orlando, FL in 1991, and only has 4

hours on the Hobbs:

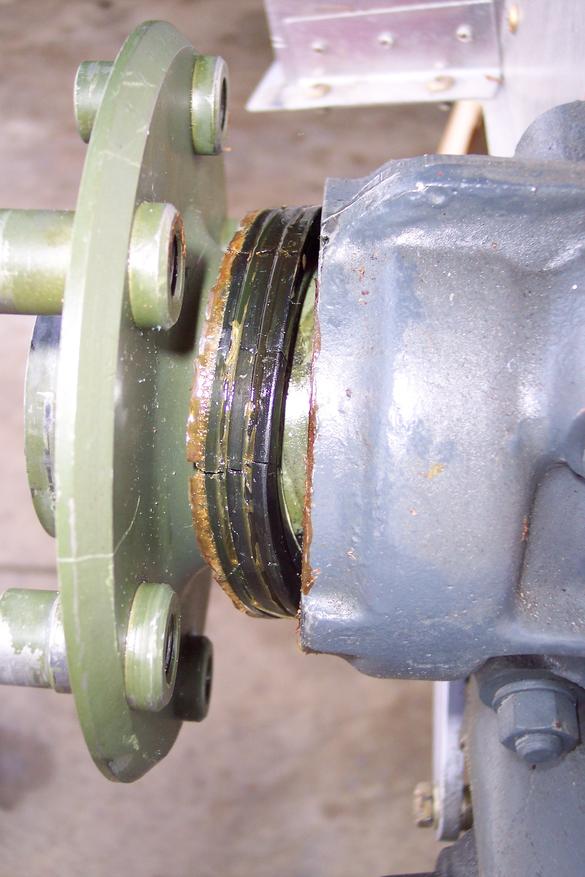

Look at all the cracks in the seal! It's no wonder that oil was

leaking out! Furthermore, when I started cleaning out (with M.E.K.)

the recess where the seal went, I noticed that there were several

pieces of silk thread intruding into the seal area at the case part

line (another mirror shot). I cut the silk thread off with a

sideways razor blade on a stick:

I'm just posting this for information, but all comments are welcome,

as always.

I plan to use the

EAA

method as well as

Lycoming

Service Instruction 1324 to reinstall the new seal. Wish me

luck.