Hey LML

gang,

A big thanks

to everyone that responded to my request for comments and advice regarding in

flight engine fire suppression. There were three main questions

raised:

1.

Is Halon 1301

the best agent for an engine fire?

2.

How effective

would a fire suppressant be in flight with the high air flow through the

cowling?

3.

Even if

extinguished, a fire may be likely to re-ignite after the suppressant is flushed

away by the air flow.

Here’s what

I’ve learned in research related to these questions…

Is Halon 1301

the best agent for an engine fire?

Yes.

Everything I’ve found in research indicates that for this application it is the

best. It requires a very low concentration for a very short period of time

to extinguish a fire. The FAA certification minimum is 6% concentration by

volume for at least 0.5 seconds. It actually works in milliseconds,

though. It has a high vapor pressure, about 200 psi, and disperses

throughout the atmosphere very rapidly into nooks and crannies. It is also

non-corrosive and leaves no residue – so no cleaning is required if

discharged. There is also no acute toxicity for humans below 10%

concentrations.

How effective

would a fire suppressant be in flight with the high air flow through the

cowling?

This was also

one of my biggest questions and I couldn’t find any analysis on the internet to

answer this. So, I worked up a simplified but conservative analysis.

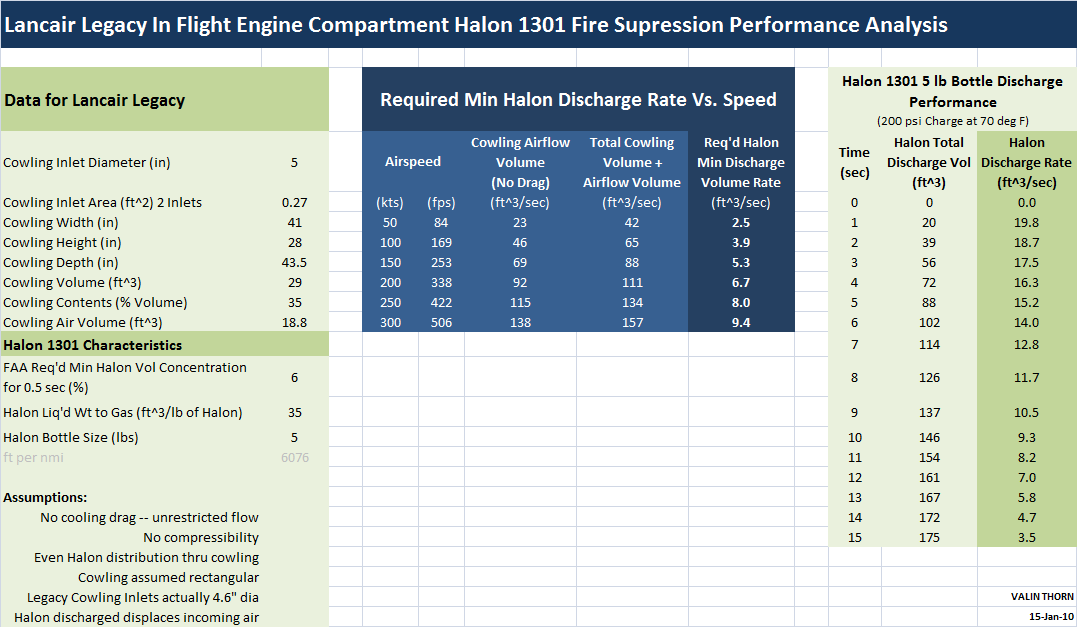

Below is a screen shot of part of my spreadsheet. I talked with

Safecraft’s Don Warren and he provided three key pieces of data on Halon

1301. He said one pound of Halon 1301 as a gas will occupy 35 cubic feet

at sea level pressure. He provided two points of data on the Halon

discharge rate from their 5 lb bottle at 200 psi. In 5 seconds 2.5 lbs of

Halon will be discharged and all 5 lbs will be discharged in 15 seconds.

So with those two points I created the table on the right of the Halon 1301 5 lb

Bottle Discharge Performance.

My basic

analytical approach was to look at the total volume of air each second that

Halon would need to be dispersed in, to see what the minimum 6% concentration

volume would be vs. airspeed. The volume required is the total airflow

volume through the inlets, for the time period being examined, plus the cowling

volume. I made conservative assumptions – for example, no cooling drag or

slowing down of the air through the cowling, I assumed larger than actual

cowling inlets, and larger than actual cowling (simplified as cube at max

dimensions).

I was happy

to see, that even with these conservative assumptions, with discharge of a 5 lb

bottle of Halon 1301 at 300 kts there would be 10 seconds with more than a 6%

concentration of Halon to knock down a fire (only a half second required for

spec). You see this by comparing the Halon Discharge Rate to the Required

Minimum Discharge Rate vs. Airspeed.

After doing

this analysis, I found a reference in a magazine article that pointed out that a

6 lb bottle of Halon 1301 is all that’s required on a 747’s engine to knock out

an engine fire… So with this analysis and the 747 benchmark, I’m convinced

a 5 lb bottle of Halon 1301, with proper positioning of discharge outlets in the

cowling, can knock down an in flight engine fire on a Lancair

Legacy.

Even if

extinguished, a fire may be likely to re-ignite after the suppressant is flushed

away by the air flow.

Yes.

And of course LML’ers have pointed out that the proper procedure is to shut down

the engine, cut off the fuel flow, cut off electrical power, and then discharge

the Halon. So you don’t want to do it too fast – before cutting off

potential fuel and ignition sources. One interesting thing I found in

research was reference to an Air Force study that found you also don’t want to

wait too long to put out the fire because it will eventually heat things up so

much that the hot parts may serve as re-ignition sources. They said the

suppressant should be discharged within 14 seconds after the start of the fire

for the cases they were studying. So there’s too fast and waiting too

long… One advantage of going with a 5 lb bottle, which is much more than

required to knock down a fire in a Legacy, is that it will ensure additional

time to allow the airflow to cool things off to help reduce the risk of fire hot

parts re-igniting the fire.

As a passing

note, Halon 1301 systems are only certified up to 130 deg F operating

environments so the tank should not be installed under the cowling – somewhere

in the cabin is best. If you only have room to put a Halon system under

the cowling you should use Halon 1211 which is certified for up to 200 deg

F. The downside of 1211 is that is has a much lower vapor pressure and

will require more attention to the discharge nozzles for good dispersion in the

space. BTW, 1211 is the recommended Halon for cabin extinguishers because

it discharges in a stream before vaporizing so you can aim it accurately at the

fire.

Anyway, I

wanted to share this with the community for those considering fire suppression

systems and hope this is helpful. Thanks again for everyone’s

advice. Let me know if you have any comments, questions or find errors in

my analysis I need to correct.

Fire

detection is a critical part of a fire suppression system and I’m still studying

options there…

Thanks,

Valin

Thorn

Legacy under

construction, still

Houston,

Texas