Mike wrote: I was working on the shimmy problem

a couple years ago when a bunch of the ES guys were dealing with shimmy.

I did some temperature tests on BelRay 30W. I used a Zahn cup to measure

viscosity so my measurements were time measurements. I tested it at 60F,

90F, 120F and 180F. From 60F to 90F its viscosity was cut

in half. From 90F to 120F it was cut in half again. So from

60F to 120F the time for the oil to flow through the Zahn cup was 1/4.

I'm not sure of the science of damping vs. viscosity

measured with a Zahn cup, but the struts are definitely affected temperature.

After running my tests and posting them to the ES group,

some of the guys suggested some very high quality multi-viscosity motorcycle

racing strut oils like Spectro. They only performed slightly better than

the BelRay 30W.

The new style strut uses hydraulic fluid which doesn't

change viscosity with temperature. I tested it too.

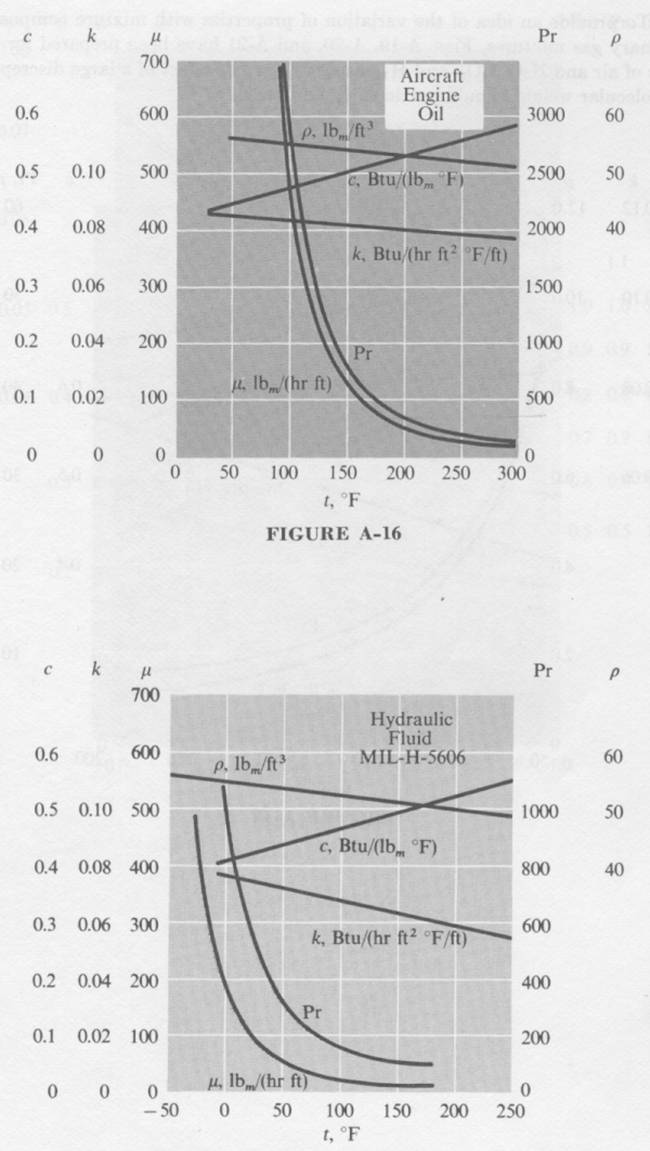

Here is some data from Kays, Convective Heat and Mass Transfer. Absolute viscosity (which

controls damping via creation of friction losses from fluid shear) is plotted

as “mu” which parallels the Pr line (Prandtl number, ratio of

momentum transfer to heat transfer of a fluid). You can see that

hydraulic fluid is “runny” with low viscosity at the temperatures

of interest, fine for transferring hydraulic pressure, not so fine with highly

loaded journal bearings (think crankshaft). The curve for hydraulic oil

looks like it is flat near the bottom, but if you blew it up, you would see

that it is still falling rapidly, on a percentage basis. Most liquids

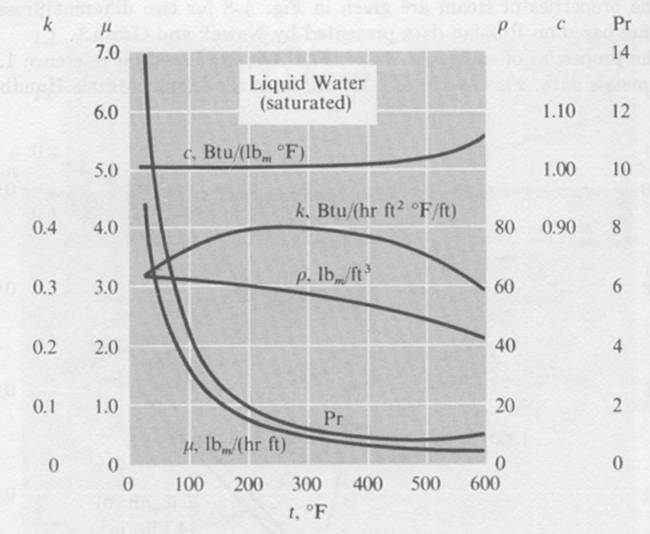

have this same viscosity vs. temperature characteristic. For jollies I

put a chart for water at the bottom. Note the scale change. Water

also “thins out” dramatically with temperature.

For aircraft engine oil increasing the temperature from 100F

to 200 F yields about a TEN FOLD decrease in viscosity. (No SAE number is

given, but I would guess SAE 60 for radial engines.) With hydraulic

fluid, one would expect roughly the same magnitude of viscosity decrease with

temperature, but the data is too close to the horizontal axis to make a guess,

and quits before reaching 200F.

The critical lesson in all this is just what Mike said: “…the struts

are definitely affected temperature.”

And how. Fred