|

McCauley Prop Governor Unfeathering

Accumulator

McCauley Contact Info

Product

Support:

Hal

Bohannon, Manager

Gary Peak, Service Engineer

Chris Bell, Service Engineer

James Williams , Technical Training Administrator

Leah Hammar, Engineering Technical Aide

Mailing

Address:

McCauley Propeller Systems

PO Box 7704

Wichita, KS 67277-7704

Phone:

316-831-4021

Toll Free:

800-621-PROP (7767)

Fax: 316-831-3858

Support:

productsupport@mccauley.textron.com

Explanation:

http://www.mccauley.textron.com/prop/prop-tech/pg02var-ptch.html

A full-feathering

propeller system is normally used only on twin-engine aircraft. If one

of the engines fails in flight, the propeller on the idle engine can

rotate or ?windmill,? causing increased drag. To prevent this, the

propeller can be ?feathered? (turned to a very high pitch), with the

blades almost parallel to the airstream. This eliminates asymmetric

drag forces caused by windmilling when an engine is shut down. A

propeller that can be pitched to this position is called a

full-feathering propeller.

http://www.mccauley.textron.com/prop/prop-tech/pg04feather.html

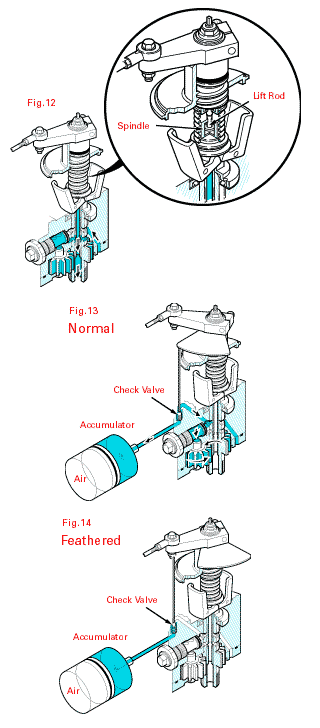

The unfeathering accumulator

option permits a feathered propeller to be unfeathered in flight for

air-starting the engine. With this option, the governor is modified to

provide an external high-pressure oil outlet through a check valve, as

well as a device for unseating the check valve. The external outlet is

connected to an accumulator. One side of the accumulator is filled

with compressed nitrogen and the other side with oil. This allows the

oil to be stored under high pressure, as it is during normal flight.

(Fig. 13) When the propeller is feathered, the check valve maintains

oil pressure in the accumulator. (Fig. 14) When the propeller control

is moved from feather to low pitch, the check valve is unseated,

permitting the high-pressure oil in the accumulator to flow to the

governor pilot valve. With the governor control lever and shaft in low

pitch, the speeder spring forces the pilot valve down so that the oil

flows to the propeller and moves the blades to low pitch. (Fig.

15)

Feathering

Governors

Feathering governors were

developed to maintain a constant speed on the feathering propeller as

the name implies. The basic feathering governor model is identified by

the alphanumeric callout of DCF290D(X)/T(X). Twin engine aircraft

benefit from the safety of the use of the feathering propeller control

system. The feathering governor uses oil from the engine to

hydraulically maintain a given speed setting and allows the pilot to

feather the propeller in the event of a loss of power or other engine

problem. Feathering the propeller eliminates that would be caused by a

wind-milling, non-feathered propeller. This gives the pilot the

ability to fly the aircraft with one engine to the nearest airport for

repairs.

.

http://www.mccauley.textron.com/prop/propframese.html

Feathering Governor Options: Unfeathering

Using the basic feathering governor (DCF) many options can be

added to increase safety and comfort of the passengers. Some

feathering governors have been designed to include the option of

unfeathering. The basic unfeathering governor model is identified by

the alphanumeric callout of DCFU290D(X)/T(X). The unfeathering option

allows the pilot to unfeather the propeller if desired after it has

already been feathered. The unfeathering systems includes a McCauley

unfeathering accumulator which provides high pressure oil to the

propeller to "push" the propellers blades out of the

feathered position by using stored oil to move the propeller

piston.

|