“Soldered stranded wires will

eventually break off if soldered, it makes a shear point.

If you need further proof I would

suggest you convince yourself. Do an experiment. Solder the wire to the

connector. Wiggle it up and down. With the connector fixed to something hard

so it won't move.

See how fast it breaks.

Now do the

same with a crimped connection. If using an un-calibrated tool, play with the

force you use to crimp the wire. This will allow you to form your own opinion.”

But it may not be a well informed

opinion. Please consider the following and then you can make a somewhat better

informed decision.

The observation above makes an interesting

secondary point, but it is only SECONDARY. Keep in mind that many military/aerospace circular connectors have solder

cups on the back of pins already in place, so clearly under some circumstances solder

joints are acceptable even in these industries. But as noted in prior

discussion, the key is not the solder or crimp joint, but rather the quality of

the execution. It is easier to crimp and get a high quality joint than to

solder and get a high quality joint, but that does not mean solder is out of

the running.

The PRIMARY point in getting a

reliable termination is to make sure that there can be NO RELATIVE MOTION

between termination and wire – no flexing, no vibration movement,

nothing, nada, zip.

Wiggling is forbidden! Otherwise

the termination will likely fatigue and fail sooner or later. You can get away

with lousy workmanship and practices in stationary installations, but in

aircraft where there is vibration or (sometimes more important) cable flexure

arising from working with cables in the aircraft (maintenance induced

failures), it is more important to make sure there can be no relative motion

between wire and termination. Crimp versus solder controversy is secondary.

BOTH can be made to work satisfactorily, and more reliably than a connector.

This is the key. Both rely on NO RELATIVE MOTION to ensure continued joint

integrity.

Shift your focus for a moment from

the termination to the STRAIN RELIEF, the thing on the connector aft of the

termination that clamps onto the wire bundle. It is there to carry the

mechanical loads from the wire bundle to the connector shell, and to entirely

eliminate any relative motion between wire and

the termination, be it crimp or solder. No strain relief, no reliability. THE

STRAIN RELIEF IS AS IMPORTANT AS THE WIRE TERMINATION, maybe more so. Note

that the strain relief clamp has to clamp tightly onto the cable. This may

require adding diameter to the wire bundle; most commonly with silicone self

stick tape, to get good clamping action on the wire bundle. Here is an

example.

Note that the wire bundle is small

so the tape is used to increase the diameter, and coincidentally minimize the

chances of the clamp cutting into a wire if it is over tightened. Note also

that the wire shields (from twisted pair shielded lines) are connected to the

cable shell for maximum noise protection as suggested in some equipment

installations. Follow equipment installation instructions when it comes to

handling shields.

But the ideal is to connect wires WITHOUT

connectors to eliminate the potential fallibility of the connector. The goal

is to approach the reliability of a continuous wire in a wire run. You can do

this with crimp connections or solder connections. Either must be properly

executed to achieve the desired level of reliability, that is, better than a

connector.

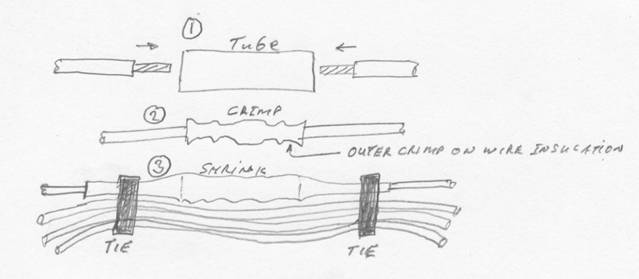

The most common crimp connection for

wires is with the little tube. Put a stripped wire end into the tube, then

crimp. But you are not done. Now you need to stop relative motion between

wire and crimp. Shrink tubing over the entire thing helps, but frequently shrink tubing that fits over the

tube is too large to close tightly over the wire to stop the relative motion.

And the shrink tubing is not as rigid as a cable clamp. So better is to

shrink, and then tie both ends of the connection beyond the tube crimp

connector to the bundle to get some rigidity and stop the potential relative

motion.

The problem is that a bunch of

these tubular crimps and shrinks can lead to a big bulge if you are connecting

a lot of wires in a bundle as from panel to airframe. You can end up with a

bundle that looks like the python that swallowed the rabbit. And this

normally occurs where space is at a premium.

The place you really get screwed is

if you have to separate the wires and then reconnect. Your only option is to

cut the wire where it enters the tube crimp connector, and you lose some

length. Better have some spare length somewhere!

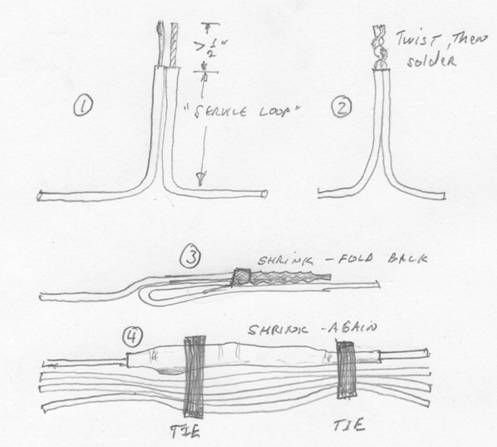

The same result can be achieved with

a solder connection which can later be separated with no or minimal loss of

wire length for subsequent reconnection. The steps are as follows:

1)

Include

some spare length in the wires to be connected. This allows for later

disconnection and reconnection which may require cutting the soldered portion

of the wire and re-stripping.

2)

Strip

about ½ inch or more off each wire.

3)

Twist

the wires getting at least three twists to make a good mechanical connection

between wires.

4)

Solder

the twisted pair.

5)

Shrink

tubing over the joint AND some wire insulation.

6)

Fold

the connection back against one or the other of the connecting wires.

7)

Shrink

tubing (next larger size) over the entire junction.

8)

Tie

into wire bundle.

The resulting joint prohibits

relative motion between the two wires at the junction. Mechanical forces are

transmitted through the wires and through the outer shrink tubing when you mess

around with the wires subsequently, and then all is locked down when the bundle

is tightly pulled together and then anchored somewhere.

This solder method yields a

connection that can be as virtually as reliable as the unbroken wire, which

means it is more reliable than a connector. The joint can also be smaller than

a completed crimp connection, and by staggering the joints along the wire

bundle length, the rabbit in the boa constrictor bulge can be largely avoided.

Crimp enthusiasts can use this same

technique if using the single ended crimp caps or cups instead of the solder

joint. The trick is to find these in small diameters. You won’t find

them at a hardware store which stocks only the big ugly stuff for 10 gauge wire

used by house electricians.

So, some may prefer crimp

connections (which require a bit less skill, but still require a good crimper

that can deliver a double crimp, one on metal and one on the insulation, so ya’ll

strip and insert and crimp carefully!) and some may prefer solder. Both

require that the subsequent joint be immobilized to assure that there will be

NO RELATIVE MOTION between wire and termination. Both can be made to work

reliably, but both require attention to detail to be most reliable.

Key notes:

1)

As

noted previously, use high quality crimpers. For connecting wires to one

another be sure to use racheting crimpers that will not release until the job

is done. For my crimpers, this frequently means squeezing with both hands to

get the damn thing to release, but then the joint is well and truly crimped. The

photo below shows an OK crimper and a junk crimper. Throw away the junk

crimpers.

2)

If

you decide to use crimpers, go with gold plated pins wherever possible. FOR

SURE use gold (or silver plated pins on some coax connectors) on low level

signal lines from transducers and on antenna lines. The voltage levels on

these lines are down at the microvolt or millivolt level. If you use a

non-gold plated connector, a thin molecular layer of metal oxide between mating

parts is enough cause an open circuit and error. Fourteen or twenty-eight

volts is enough to punch through the thin oxide layer, so cheaper tin plate

connectors (like some Molex connectors) are marginally acceptable on these “wet

contacts,” but for signals from pressure transducers, flow meters, fuel

tank sensors, etc. tin plate connections are not reliable enough in “dry

contact” applications and can develop a very thin film of corrosion. Particularly

in humid areas, the low voltage can not punch through the oxide layer. It won’t

happen this year or next, but becomes more likely with the passage of time.

3)

When

troubleshooting sensors and antennas, start by disconnecting and reconnecting

connectors. The wiping action cleans the contacts, and may restore the

integrity of the connection.

4)

Pay

attention to detail.

Before we quit, let’s go back

to fundamentals. Why do you want connectors between panel and airframe in the

first place? To ease subsequent troubleshooting? I fully understand the pain

of working behind the panel, particularly with a steeply sloped windshield as

on the Lancair. Let me suggest another alternative – a simple panel

hinging method. See below.

I tried the piano hinge behind the

panel anchor point, but was not satisfied. It was a pain to get holes aligned

because my panel is already assembled and hard to handle. So some

brainstorming with a friend yielded the solution above.

1) Cut the lower flange off the

anchor point on the panel. Its absence is visible in the photo on the right

where the flange used to occupy the slot in the wood stand.

2) Build a carbon flange onto the

panel. I already had the attachment holes drilled, so I put 4 BID on the

front, then drilled through the carbon from behind, then put 2 BID behind and around

the flange, and drilled through this from the front to preserve the hole

locations. Extend flange down below bottom edge of the panel where it bends

around parallel to the fuselage.

3) Drill a ¼ inch pivot hole in the

flange even with or slightly below the bottom edge of the panel so that the

panel can rotate down without interference.

5) Make up a phenolic block thick

enough to span the distance from flange to fuselage wall. Drill and tap ¼-28

6) Install panel, grind phenolic

blocks to match sidewall of fuselage, then flox the blocks in place and align them

while the flox cures by putting in a ¼-28 bolt of appropriate length. The panel

can now fold down about 60 degrees from horizontal as long as your wire service

loops are long enough. Don’t forget to disconnect struts and other

anchors before flipping down! Have a pre-cut piece of wood with foam to hold

up the panel when folded out, or use a cable to suspend it from the roof.

7) The forward portion of the

armrest ahead of the stick needs to be removable to allow the panel to fold

down. That is why I have the anchor nut on the top of the flange as shown. The

armrest will anchor here and on the sidewall when installed.

Fly safely.

Fred Moreno