To the impatient,

First, much thanks to George,

Walter and Tim for an extremely informative presentation and facility tour. Special thanks to Mike for organizing

the un-organizable Lancair special interest community – those hot heads that

want cooler heads.

The basic thrust of the

presentation:

Under the assumption that enough

cooling air is present and adequately departing the bottom cowl, the

presentation focus was on making sure that the cooling air was passed thru the

cylinder head fins. The majority of

the heat is generated at the top couple of inches of piston travel – thus one

must pay attention to using all of the fins at the top (upper) portion of the

cylinder to dissipate the heat generated in the cylinder. Remember that there are conditions that

affect how much heat is generated by the combustion event, FA ratio, peak

pressure timing, power, etc. Again,

this discussion will be directed to making the engine baffling work to maximize

heat removal by making the available air reach all the cooling fins.

The following also assumes that

the cooling is top down with the engine in a tractor configuration. A primary difference between Continental

and Lycoming is that the valve push rod tubes are on the cylinder bottom for

Continental and the top for Lycoming thus making some bottom baffling

requirements more challenging for the Continental (in my opinion).

A) Many baffle setups do not

completely route cooling air around the fins on the lower portion of the

cylinder even though they look pretty from above.

B) Some arrangements for other

uses of cooling air (intercoolers, oil coolers) may block or create low pressure

areas that rob the cylinder head of adequate airflow.

C) Both Lycoming and Continental

cylinders have a “flat” side that does not allow air to flow to the lower fins

because of the baffling, except at inter-cylinder locations.

D) Some cylinder locations can be

super-heated by infrared radiation from the exhaust stack and the impact is

fourth order as the temperature of the exhaust increases. This condition must be examined for

appropriate shielding.

Yes, readers will have to remove

both the upper and lower cowling to evaluate the performance of their

baffles.

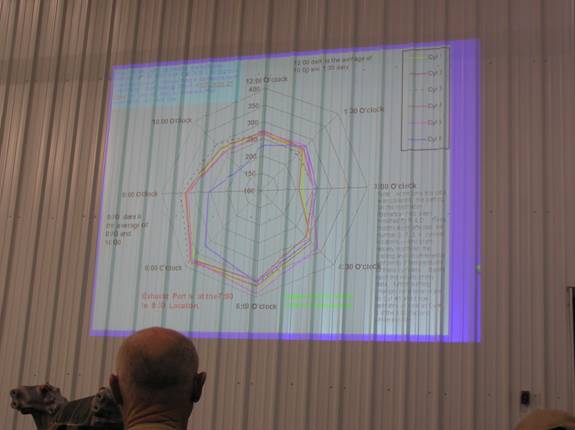

The slide below depicts measured

cylinder head temperatures (I don’t have the notes on exactly what the

conditions were) around the cylinder for various cylinders (Bonanza). Note the

temperature spread around the cylinders and the difference between some. CHT probes are located at the cyl bottom

– seemingly the hottest location.

Also, note that more even cooling around and between the cylinders would

be less stressful on the engine.

Specifics for (A):

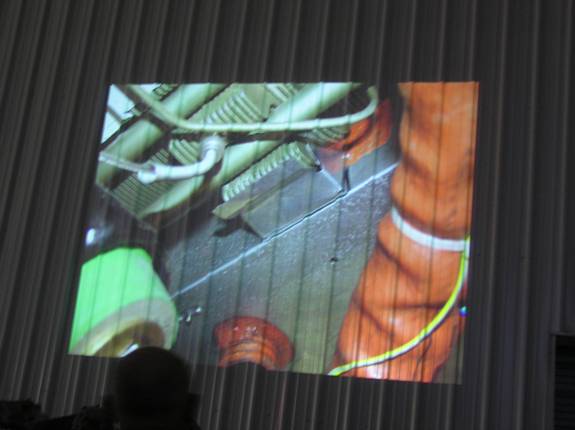

The picture below (blurry that it

is) shows a baffle addition with a fence to better direct air to some bottom

fins. It is your job to figure out

what cylinder it is for. This

typifies some of the cylinder areas that have to be examined.

Specifics for (B):

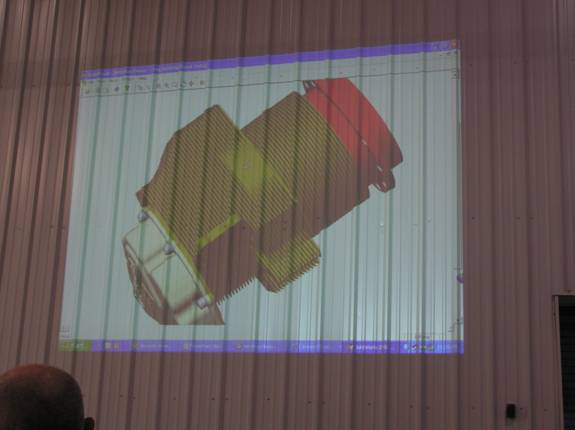

The oil cooler below deflects a

great deal of cooling are over the top of the cylinder behind. One recommendation would be to put a

“curved wing” about 3/8” above the top of the cooler to direct some air flow

down to the face of the cylinder.

Another problem depicted below is

the creation of a low pressure area near the cylinder because another air flow

user is drawing off a great deal of air.

George Kool-Aide Braly tried a scoop (or roof) behind the cylinder to

direct air down but says that did not work because of the low pressure. Instead he built a vertical fence along

side the intercooler that was baffle sealed to the upper cowling and extended

just forward of the necked down part of the intercooler. Cylinder cooling was restored.

Specifics for (C):

The above picture also

demonstrates the problem described in (C).

Below shows the “flat spot.” This is troublesome on the fwd right cyl

and back left cyl on the continental engine and the fwd left and back right (??)

on the Lycomings – at least it is on my 4-cyl 320. Troublesome because air cannot pass from

above the spot to below without some baffle work.

The picture below shows an

additional hole to get air to the lower baffle although George recommends a

“roof” (maybe even with sides) is used to direct the airflow down.

See the opening? See it behind the B-lead terminal on the

alternator? Two pix back one could

work that in below and behind the landing light.

I hade modified my 320’s cyl two

baffle to better allow air to the fins at the lower front quadrant and cyl 2 is

no longer the hottest. Maybe I can

get a picture of that mod posted soon.

It is time to fix the baffling behind cyl 3 to cool that one better

also.

Specifics for (D):

Darn, no picture! When you look underneath the engine, you

will see that some baffle extension will be needed on fins adjacent to the

exhaust port. It is useful to

enclose the extension with full side walls to ensure the air doesn’t spill out

before cooling the fins. Another

benefit is that the side nearest the exhaust also becomes a radiant heat shield

so the fins aren’t additionally heated by the nearby exhaust pipe. The exhaust system should be examined

for where radiant heat may affect components, including the cylinder head. Some things can be shielded with

aluminum on the “thing” or a stainless steel standoff shield may be attached to

the exhaust pipe with a SS hose clamp.

It’s a beginning. Good luck and stay cool.

Thanks again to George, now known

to me as Mr. Kool-Aide from Ada.

Requires hot and cold running air.