|

|

In a message dated 12/31/2003 10:33:37 AM Central Standard Time, 13brv3@bellsouth.net writes:

<< Hi Lynn. Thanks for the great explanation. I didn't really understand the

above statement though. My assumption was that you should have the tube OD,

the same as the flange ID. If that was true, how can you keep the tube from

touching the sides of the hole in the flange? Are you saying that the tube

should not extend beyond the flange, so that it touches the engine itself? >>

Seldom would the tube fit the hole exactly in any installation. So a die grinder or a rat tail file to adjust the hole size would be required. A good fit would be where the tube ID is just slightly bigger than the exhaust port.

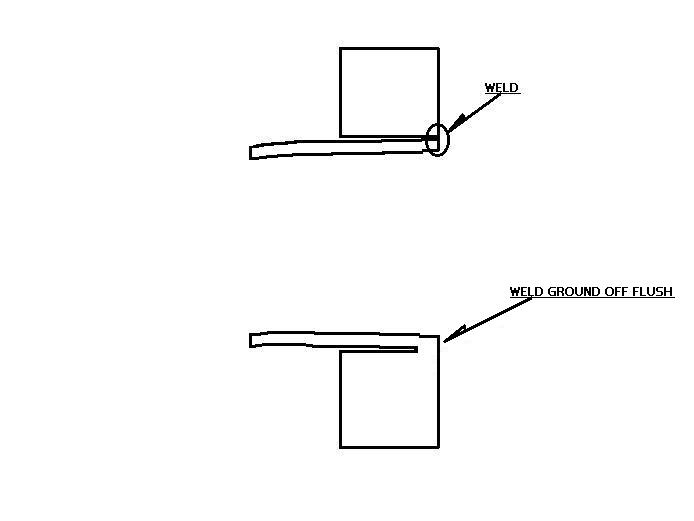

If the tube size fits the exhaust port near perfectly, you would check for a fit as in the picture. Do the fit up with a very short piece of tubing stuck through the flange.

If the flange hole is too small, then the file or die grinder would be used to adjust the hole in the flange to fit around the tube. If the hole is off center you may want to add weld material to one side of the flange hole and smooth with the die grinder. I would leave the stud holes through the flange as small as possible, and leave the flange in one piece, to maintain some form of register. Once the flange is fitted with a scrap of tube in each hole. Fit up one header tube. You can tap the inside of the tube end with a ball peine hammer while resting the very end of the tube over the rounded nose on you big anvil. The tube OD can be increased very quickly this way. So, the flange holes would end up centered over the ports, with the flange hole ID just a bit bigger than the tube ID. Then the tube ID is increased slightly to fit the hole tight but only at the engine side face. Then you tack it on the inner face and recheck everything about 6 times for everything clearing everything else. Have somebody else look at it and make them ask you all of the questions you should have asked yourself. Like, will I be able to remove this header once it is all one big piece, without removing the engine? And doesn't the radiator go right there? Can I get a socket on all of the mounting nuts? Can I safety wire anything at all? And so on....

None of this is all that important. With stainless, the cracked tube is far less of a problem than with carbon steel. But it also costs nothing extra to do it right. Look at the carbon steel headers at the hot rod shop. Most are done just as above.

TIG with great penetration, or have it done. I use RTV as a sort of gasket. If there is no gasket, it cannot blow out. I put it on thicker around the outer parts of the flange and thinner close to the hole. Let it gel up for 10 minutes before you torque it down. Any bit that extrudes into the port area will vanish. Retorque after the first heat cycle. No leaks since 1980. You must grind the whole flange dead flat once all of the welding is completed.

Lynn E. Hanover

Flange.jpg

|

|