|

|

In a message dated 12/22/2003 9:42:38 AM Central Standard Time, sqpilot@earthlink.net writes:

<< Hi, Lynn and thanks for the response. Any idea what type of decibels the

rotary would produce without a muffler, ie....straight pipes? I don't know

what the spintech muffler DB measures behind Tracy Crook's aircraft. Still

searching for a muffler that will stand up to the heat and pluses of a

rotary. Since I have a pusher, I don't want things coming out of the

muffler, as they would go through my prop. Not a nice thing. Thanks again.

Paul Conner

There may not be a scale that goes that high. We added a muffler before it was required. It is so loud that the driver cannot think. It is not only way too loud, it is not a good sound like a Chevy V-8. It is an obnoxious sound that nobody likes.

The Spintech and Flowmaster both seem to work well. Some schemes, where the pulse is broken up as in case of the Spintech, or split into two parts and directed against itself as in the Flowmaster work the best.

In a short system, there is no room for a muffler that can readily disintegrate. So that leaves out the Flowmaster because I know they will disintegrate. They are flat sided and tend to melt and be hammered to pieces when close to the rotary engine. The Spintech should work better even though it is flat sided, each fin set is welded to the sides, so it should stay together for some time. The homogenizing mufflers look interesting, but would eliminate any tuning effect if the header is not collected before entering the muffler. I would build a combination of both the Flowmaster with a thick walled splitter in the front of the chamber, and then the turning vanes of the Spintech, all in stainless.

I would design a system with the idea in mind that every single part is, at one time or another, going to burn through at the worst possible location and time, and after doing the greatest amount of damage, will fall out and go through the propeller arc, striking every blade. If you stress any metal while it is at a very high temperature, it will fail sooner than at any lower temperature. So, the engine would have short stainless stacks. One slip jointed down tube would have the collector welded to it. One side of the collector would have another slip joint for the second down tube. This so no stress could be applied to the engine or the collector.

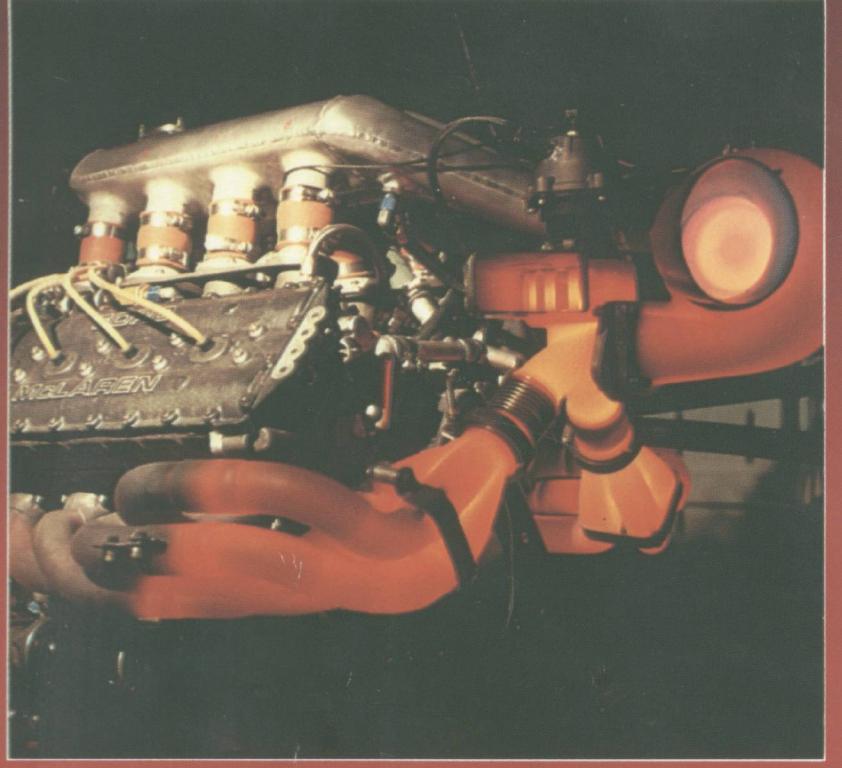

Each slip joint would have a stiff spring on each side pulling the joint together and overlapped tabs with a hole through both, with a loose cotter pin or nut and bolt, just in case both springs break. The tabs for the springs would have a safety wire hole close to the spring mounting hole, so that a doubled run of loose safety wire can run through the center of the spring for when it breaks, so the pieces cannot escape. The muffler would be mounted stiff to the engine mount. A flex joint at the muffler "in" junction and the flex joint at the collector would give enough movement for the engine to flex about in the mounts without overstressing the exhaust system tubes or junctions. Another flex joint at Muffler out, and a stiff hung tail pipe mounted to the engine mount. Every piece should have two tabs with a safety wire hole, so that a double strand of loosely strung safety wire could be installed the retain the piece inside the cowl no matter what has gone wrong. Not to another exhaust system part, but to the engine mount, or the engine proper. Tracy has some numbers on his Spintech, and I think he says the wind noise is louder in some situations than the engine. Check out the radiant energy being given off by this system. (See picture.) This can set stuff on fire that is over 1 foot away. Lynn E. Hanover

Engine-on-dyno.jpg

|

|