|

|

I know that Bob Pastusek keeps a file on "Limitied Life Items", so I

thought I'd add my observations (for what they're worth). As

everybody knows, I bought my L-235 kit in 1987 and have been working

on it for a long time. Pretty much everything made of rubber has had

to be changed out - tires, tubes, hydraulic hoses, gascolator

soft-goods, mechanical fuel pump (just bought a new one), and the

front crankshaft seal on the engine. I'm into the brake system and

hydraulics now, and have a few observations.

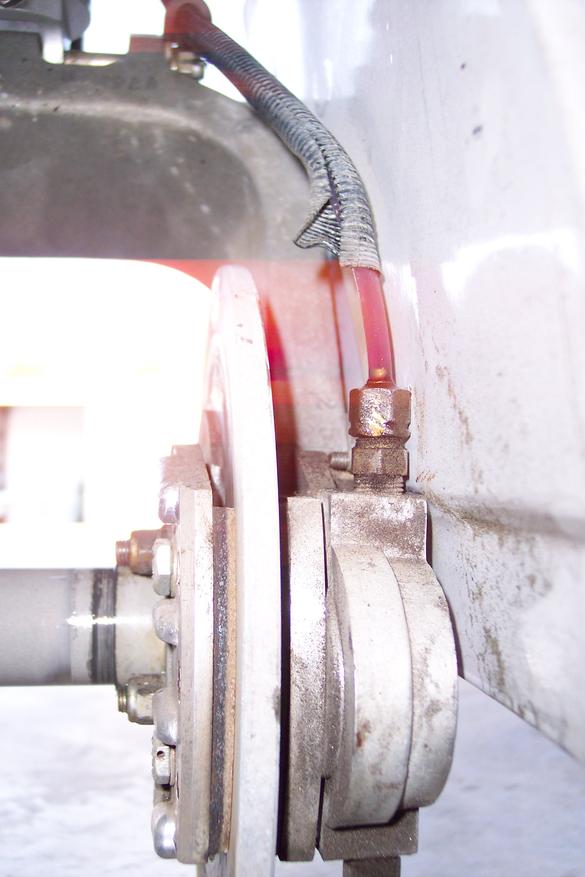

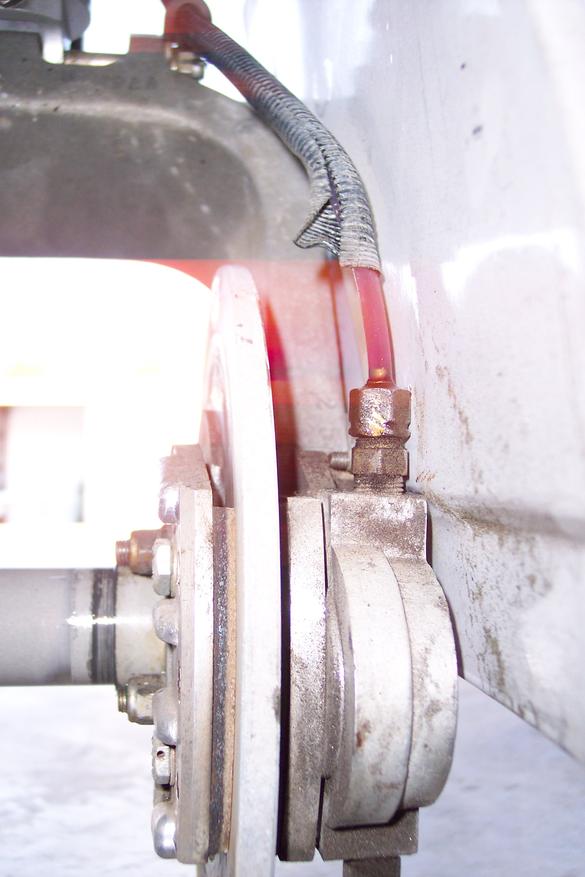

1. I removed and replaced the Nylaflow tubing to my brakes just on

general principles; I replaced it with the heavy-wall Nylaflow,

which is probably overkill. The standard-wall tubing I removed

seemed completely serviceable to me, though; It was still flexible

and no cracking was observed. While I was doing that, an older (than

me) Long-EZ builder stopped by and I asked him about the Nylaflow

tubing. He is still flying with the original 30 y.o. Nylaflow tubing

on his aircraft and has never had a problem. Down near his brake

discs, he wrapped the nylon tubing with some kind of heat-insulating

material which sounds like a great idea. During my aborted taxi

testing, my right brake disc got so hot that it discolored the paint

on the inside of the middle gear door and caused my Nylaflow tubing

to "weep" at the brake fitting. You can see a little meniscus of

hydraulic fluid on top of the brass fitting in the photo below, and

the softened convoluted tubing. The Long-EZ builder used the brass

inserts like I did at all compression fittings. We agreed that

sunlight will embrittle the nylon tubing, which is why I ran mine in

the convoluted tubing. With all the conflicting information on the

Nylaflow, I decided that I just didn't want to worry about it and

installed Russell motorcycle brake hoses for the last 18" down by

the brakes.:

2. The O-rings in the original Rosenhan brake pucks in the above

photo seemed completely serviceable after at least 15 years with

hydraulic fluid on them, and 30 years since being manufactured. I

haven't used them a lot, but there was no deterioration that I could

detect and I stretched them like rubber bands and they didn't break

- even the one on the right that got so hot. The Buna-N O-rings have

a listed shelf life of 15 yrs, if anybody cares.

3. I've had two hydraulic cylinders leak over the years. IMHO, the

primary weak point is the shaft seal; On the three that I rebuilt,

the little chevron shaft seals were falling apart. The second

weakest point (IMHO) is the piston seal which can cause a leak from

the high side to the low; I had one of them leak through. All the

end-plug O-rings inside seemed completely serviceable after all this

time. I'm just guessing here, but I would give the shaft seals a

life of 10 years, the piston seal 15 years, and the end-plug seals

20 years.

Hope this helps...

Transformed_Lancair laser wheel alignment 009.JPG

|

|