|

|

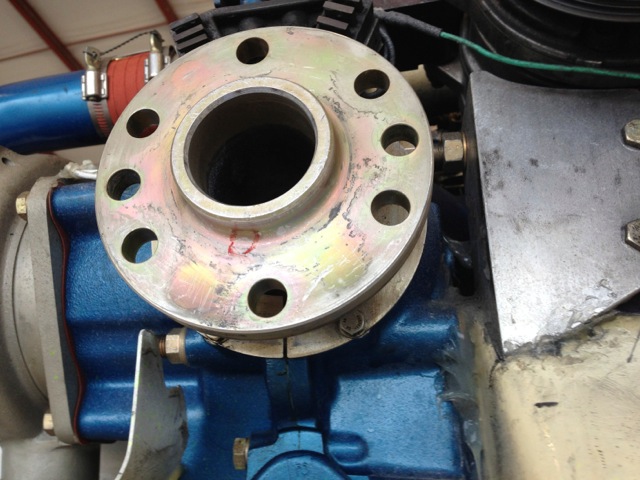

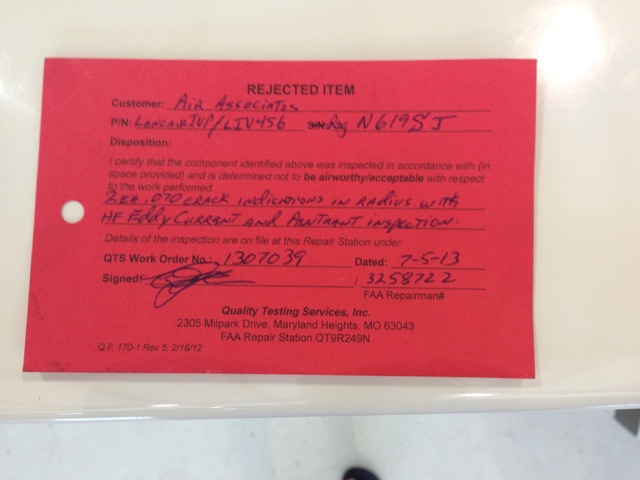

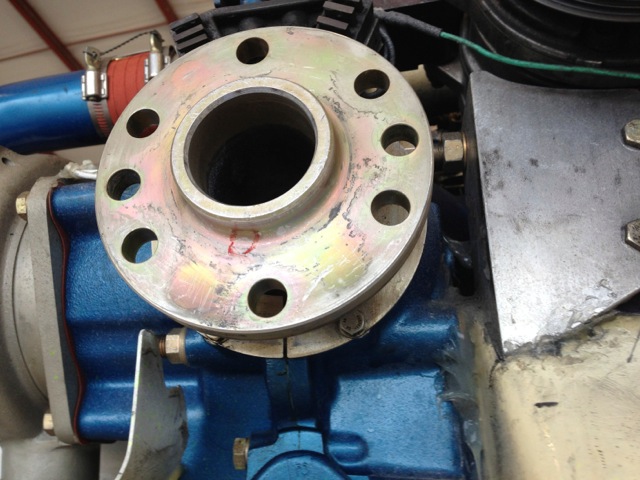

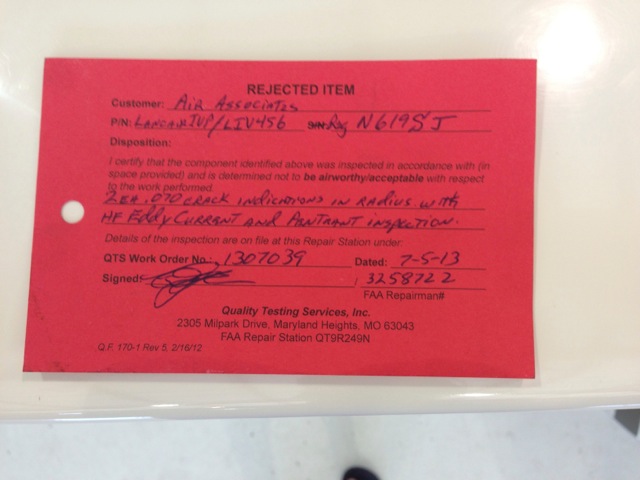

Here is a pic of the crack (red box) and red tag showing the crack data. Nothing much to look at, even in the high resolution version. I couldn't see anything with the naked eye. I did file an SDR about a week and a half ago, no response yet. As far as common issues, I have had people respond that they have exactly the same symptoms as I have had. They are all people with a big bore continental and 3 blade Hartzell prop. I don't know of anyone else that has found a crack or if anyone has tested their crank flange.

Bob,

Do you have photos of the crack? What frequency was the vibration? The same as an imbalance (~40 Hz), or faster? I realize that judging frequency is tough. How repeatably could you induce this?

I've been discussing with Colyn Case, and would like to lend a hand in chasing this down if possible. I don't have much experience with piston engine vibration or propeller dynamics per se, but I work as a structures and dynamics flight test engineer on helicopters (lots of spinning shafts, aerodynamic surfaces, bearings, absorbers, dampers, etc.). Just trying to better understand what you experienced. I'd like to measure the vibration and perform spectral analysis if there's a plane with the same symptoms. Especially if it's nearby (I live in south FL).

- Kyrilian

Sent from my iPad Gents

Lets clarify a bit. We are NOT talking about a typical persistent vibration. It is not a case of interference with the cowl or anything else like that. There are 4 reasons I state this:

1. Previous 3 blade prop did not have this phenomenon in my own installation (Aerocomposites 3 blade), and doesn't seem to be present on any 4 blade installations or any non-Hartzell props. Vibration problems sorted over 1250 hours TT before changing to Hartzell prop (by Jeff Edwards - this was his plane before I bought it!). 2. Vibration amplitude changes over time with no power changes (such as in cruise) - not typical for interference issues... 3. Vibration AMPLITUDE changes with a change in RPM. This data point got prop shop and mechanic very worried, which led me to a new prop and the test of the crank - thank God. 4. Vibration phenomenon was persistent before and after a complete overhaul (by Barrett in Tulsa). And magnaflux/ultrasound of crank at overhaul showed no problem. This rules out any crank weight problems or misfiring, etc.

So its incorrect to lump this phenomenon in with all of the other normal vibration issues we deal with as a community. With very few (known) exceptions, this seems to be localized to big bore continental engines paired with 76" (or 78") Hartzell 3 blade newer scimitar props. There are certainly those out there with this combination that do not have this problem, but there are many of us that do have it and cannot fix it by any known means - short of changing the prop. So I wouldn't rule out a compatibility problem, a prop design problem, a crank flange problem, or something we have not thought of yet.

The most important thing is for those of us who have this problem to check for cracks in the prop flange asap. If found, fix and document so we don't lose another prop in flight (or worse). In the meantime we will collect data and see where it leads us.

Bob R Agreed, I wouldn't have the nerve to pitch that to hartzell and mr brown. They are not fly by nights at hartzell. The issue is whether a common problem exists. I think Hartzell system wide manufacturing defect can be safely moved to low priority. Hartzell does a thorough vibration analysis on engine prop combinations so I don't see how something new cropped up there.

Lyc had the crankshaft issue on the Malibu, I don't recall it being related to prop at all.

I think it is a mistake to look for hartzell 550 combination as being a factor in vibration since the sample is largely hartzell and 550. You need some other way to differentiate between vibrating and non vibrating installations. I can safely say that if I found 20 contact points in the legacy over the last four years I would be cataloging those points first and confirming they are not in play. Once those are ruled out then you have something to work with. A database of 550s with and without problems may not go very far to getting a resolution.

Paul WHAT? That makes no sense at all. Where did you ever get such an idea? Danny LNC2-360 Mk-II Nothing is foolproof to the sufficiently talented fool. It could be possible for wear or manufacturing process to allow one blade to have more play in pitch operation than the others.

Blue Skies, How is that mechanically possible? All blades are attached to the same pitch change mechanisms Elton That is a possibility I had not considered, I will ask Hartzell about it. Another possibility is the movable crankshaft counter weights failing to position correctly.

Steve Colwell

It sounds to me that you may have an issue with your prop hub not changing the pitch exactly the same on all the blades. The vibration you are feeling is one blade taking a larger bite of air and then causing everything to wobble. It settles in sometimes but when you change the power setting the pitch on the prop is adjusted by the hub unevenly.

Blue Skies,

Craig Schulze

Lancair N73S

On Jul 25, 2013, at 1:22 PM, "Steve Colwell" <mcmess1919@yahoo.com> wrote:

In the first 40 hours I had vibration so severe it caused stick shake. This

has continued intermittently more or less for almost 400 hours.

First I found and fixed several Cowl Interference locations, then adjusted

and notched the hat section of the nose gear door.

At about 50 hours I paid Barrett to tear down the engine to replace the

Performance pistons (prematurely worn top rings) with stock ECI pistons.

Also found a cracked case.

We had the Kelly Alternator balanced and rebuilt at a shop recommended by

Bill Bainbridge of B & C. Sorry I can't remember the name, the Legacy file

is in Texas.

I rounded the leading edges of the elevator counter weights when building so

I temporarily squared them off to go back to the stock shape for testing.

All gear doors were checked in flight with video camera.

The pitch trim hinge pin had play, I replaced it per Chris Zavatson's web

page.

Along the way the prop was balanced twice.

I could not get more that the usual vibration (which always seemed to be too

much) on test flights. Then, unpredictably, vibration magnitude would

increase with power reduction on some later flight. I say unpredictably

because I could not get increased vibration by attempting to duplicate

previous conditions. Let's hope a solution surfaces at Airventure.

Steve Colwell Legacy RG IO550-N with Hartzell 3 Blade

-----Original Message-----

From: Lancair Mailing List [mailto:lml@lancaironline.net] On Behalf Of Paul

Miller

Sent: Thursday, July 25, 2013 7:22 AM

To: lml@lancaironline.net

Subject: [LML] Re: Potential Problem-Engine Vibration

Ed Martin's legacy is smooth. Mine has had a lot of annoying vibes as you

describe but virtually all have been removed with lots of cowling

interference fixes and plug change. Many pilots forget the alternator can

be a wicked source of vibration and it is almost in the same plane as the

prop.

The problems I had originally were in that freq range and visible at the

wingtip also.

Paul

Bob Rickard

President, Rickard Consulting Group, Inc.

IMG_0339.jpg

IMG_0340.jpg

RCG Logo for Email.jpg

|

|