Colyn writes:

<<<Brent,

long as you are talking about

engines, can you say what was so bad about the continental that you

thought it was worth 700 hours to avoid it?

>>>

Colyn, if I didn't know better I would think you are looking to start a

brawl. You are asking me to stand on a table in a college cafeteria and

yell "PCs are better than Macs". Well....OK, let the fruit cups fly.

At the time (1992) I didn't think it was going to cost 700 hours.

Bigger diameter crank shaft. Girth matters as it improves stiffness as

a cube function.

Better cooling. None of that funky induction system in the way of

cooling air.

Funky induction system. The "Continental tuned induction" thing is a

myth because the you can't split flow the way they do. The proof is,

and according to George, that GAMI injectors make a bigger improvement

on Continentals then Lycoming. If they started balanced then how can

they be improved?

More experience with 350 Hp class engines. The Continental is an

uprated 310 Hp engine. The Lycoming was designed for 350 Hp and has

thousands of engines in this size in service. Parts are available

worldwide. Core engines (for installation development) were ubiquitous

and cheap ($5K).

Mechanics I talked to said that they made more money from Continental

owners they Lycoming owners.

Top aerobatic planes invariably use Lycomings (and they still tear the

props off from time to time).

Continental has proprietary alternator and starter.

Pressurized mags that love to corrode.

Malibu vs. Malibu Mirage.

Other than that, no reason at all.

Not to say the Lycoming didn't have some problems. In particular the

intake plenum shares a wall with the oil pan. Good for naturally

aspirated engine ice prevention but bad for turbo temps. Low

compression pistons (high compression available). Crappy prop oil slip

ring passage. High mounted cam shaft, out of all that pesky oil.

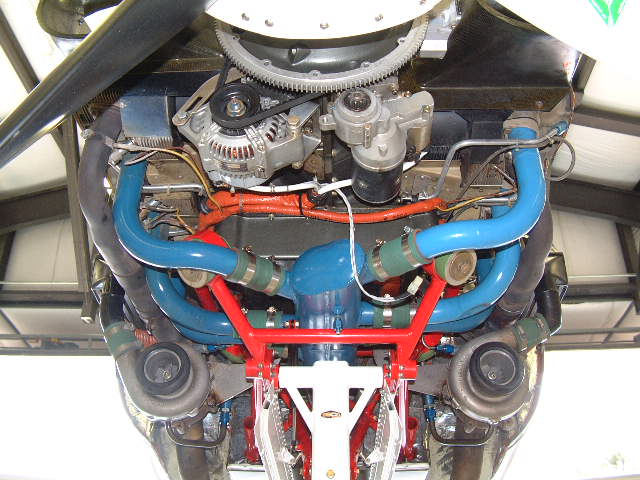

In the end I built a high compression engine (8.5:1) with low max

manifold pressure (35"Hg), high volume oil pump, custom induction and

exhaust systems and a new sump with bed mounts so I could use the

stock Lancair engine mount. It also had a sealed upper plenum plus some

other voodoo speed mods.

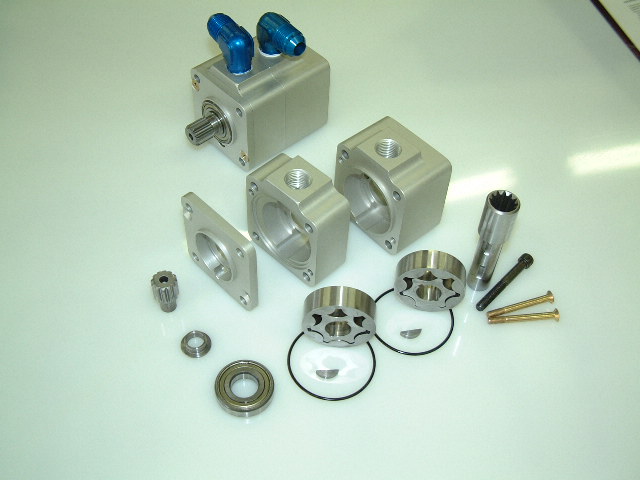

The only nagging problem I had was marginal turbo oil scavenging so I

eventually designed and built a dual input scavenge pump. Problem

solved.

I built 8 sets of parts to amortize the engineering and NRE costs and

then sold the design to Lycon in CA.

Regards

Brent Regan

DSCF0790.JPG

DSCF0792.JPG

DSCF0787.JPG

Dual Pump Parts.JPG

|