|

|

Preamble:

All aircraft , turbine and

reciprocating, should pass a fuel supply

flow test prior to first flight. A pump and regulating valve should be

configured to draw fuel from the airframe at the maximum anticipated

rate until the airframe fuel is exhausted. The aircraft deck angle

should be the same as the deck angle experienced during a go around.

You should test for the condition that would arise at the end of a

flight where you are on your third approach at the alternate airport

with critical fuel and you are forced to go around. Full power, high

deck angle, low tanks is not the time to find out you have 5 gallons

less usable than you thought.

What follows is a discussion of the existing L-IVPT fuel system (w/

belly tank)

and how it can be configured to reduce the opportunity for pilot /

operator error.

DANGER: This is a long post on an obscure topic of interest to a

limited few. Reading on may cause drooling, incontinence or even death.

If death persists for more than four hours, call your physician.

Given that flames and Jet-A are only good in confined amounts, I want

to start by saying that the factory fuel system has demonstrated that

it is safe. It can be operated in all flight configurations and

performs as required. Certain aspects of the fuel system require the

operator or pilot to follow certain procedures in order to achieve the

desired level of operational performance. For example, a system with a

left –right selector requires that the pilot select the correct tank at

appropriate intervals in order to use all the available fuel. If the

pilot fails to select the correct tank an unsafe situation may result

that is not due to the intrinsic safety of the fuel system.

As a staunch believer in the fallibility of humans it is my policy to

minimize the opportunity for human and mechanical failures in systems

design. It is my opinion that the current L-IVPT fuel system

can be

improved to reduce the opportunity for operator error and mechanical

failure.

The current system treats the belly tank as a bulge in the fuel line

between the wing fuel selector and engine. Think of it as a very short

and very fat piece of fuel line. Because of its volume, air or vapor

can accumulate. This gas is dealt with by an electrically operated

normally open solenoid in the vent line. The solenoid is connected to

the master switch and is therefore closed in flight and open on the

ground. This is all very reasonable in concept.

This system can suffer several problems as a result of operator error

or mechanical failure. The solenoid valve can fail to reach the desired

state by a mechanical jam due to contamination, an electrical fault,

and failure to turn off the battery master during fueling, or, in cases

where a switch is added to the solenoid circuit, failure to have the

switch in the correct position. Solenoid failures can result in either

gas being retained in the belly tank or fuel being discharged

overboard. Trapped gas on the ground expands to a larger volume during

climb (remember that unfortunate burrito incident), possibly starving

the engine by preventing wing to belly fuel flow.

There are two other significant failure scenarios that may result from

operator error. Depending on belly tank volume and line configuration,

an empty belly tank may take as much as 50 minutes to fill (reported by

Lancair). Turning on the master before all trapped gas has vented (and

the belly is full) will shut the vent, trapping and vapors and reducing

the usable fuel volume. The other failure may result from the pilot

setting the fuel selector to the “OFF” position during flight. Now fuel

is being evacuated from the belly with no air being introduced to

replace it. Remember in science class where you put a little water in a

gallon can, heated it to the boiling point and then sealed it, removed

the heat source and watched the atmospheric pressure crush the can as

the vapor condensed? Now imagine that happening to the belly tank.

Another failure (not operator induced) could be an air leak from the

pressurized cabin into the belly tank, again displacing fuel with air.

Flight testing has also shown that in the factory configuration, fuel

will not flow from the wing to

the belly tank with sufficient rate due to static head pressure

alone. Supplemental differential pressure from the engine fuel pump

(suction) or the wing tip NACA scoop vents is required. It should be

noted that at

200KIAS the pressure recovery of the NACA scoops is on the order of

>0.7 PSI (>15” head pressure) estimated. At 90 KIAS this pressure

drops by

80%. It is this NACA recovery pressure that mandates the solenoid valve

in the belly tank vent line. Without it the pressure would force fuel

out the vent line during cruise flight or decent.

An improved system would have the following features:

The gravity only filling rate of the belly tank should exceed the

maximum engine demand rate with chilled (-40) fuel (see my posting on

fuel viscosity and temperature). A reasonable minimum flow rate may be in the 1

GPM range (60GPH) combined from both wings.

The belly vent should be able to allow gas to flow bi-directionally

with minimal pressure drop while preventing fuel from venting overboard.

Pilot interaction should be limited to selecting Left or Right wings. A

Both selection should ONLY be available if it can be demonstrated that

all available fuel can be used in all flight configurations when Both

is selected. Byzantine fuel systems with multiple valves and

configurations should be avoided.

The belly tank should have a level indicator. At a minimum this would

be a warning light at the ~80% level, indicating the presence of air in

the belly tank. A second known volume warning would be better and an

actual capacity gauge would be best.

In practice it would be best to bifurcate the belly tank with a fore to

aft vertical septum at the centerline. Large diameter lines (>5/8”)

would connect the wing root to the belly tank. Belly tank vent lines

would be routed with a positive grade from the belly tank to the top of

the wing root bay. A pickup at the belly low point (with slosh doors)

would feed a selector valve. In this configuration the belly tank(s)

become extensions of the wing tanks and can be considered just another

bay.

In reality there are several aircraft where changing the fuel

configuration would be impractical. So, the question becomes “Is there

a better configuration available without opening the belly tank or the

wings?” The answer is yes if the gravity drain rate and vent

requirements can be met.

The gravity flow rate (0.5 -1 GPM per wing) must be achieved without

allowing cross wing transfer of fuel during uncoordinated flight or

parking on a lateral slope. This can be achieved using high flow

coaxial low pressure check valves (think flap valve in a housing).

Configured properly with sufficient flow at low enough pressures and

low temperatures it may be possible to eliminate the selector valve

entirely and replace it with a simple On-Off valve feeding the engine.

Alternately the check valves could be replaced with On-Off valves or

coaxial solenoids but this introduces more opportunity for human error.

This brings us to the vent valve. This valve should allow gas to flow

bi-directionally with minimal pressure drop while preventing fuel from

venting overboard. I remembered a valve installed in the fuel vent

lines of race cars. It is called a discriminator valve and it uses a

ball that floats in the fuel which seats when it reaches the top of the

valve assembly. Air is free to pass but fuel floats the ball up and

closes the outlet.

During a recent visit to Lancair I mentioned this idea to Ross. Cleaver

guy he is he had already come up with the same idea and produced a

prototype valve using a thin walled hollow aluminum sphere. Using the

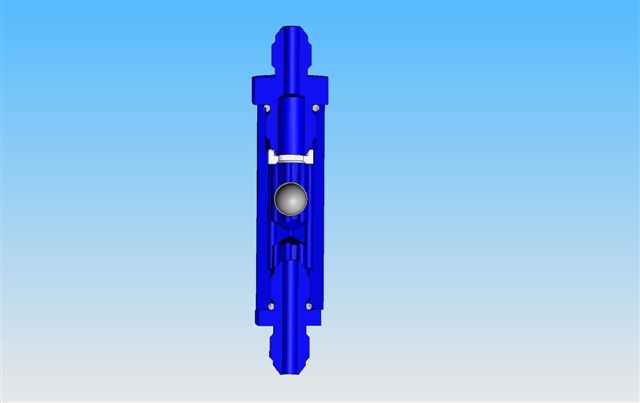

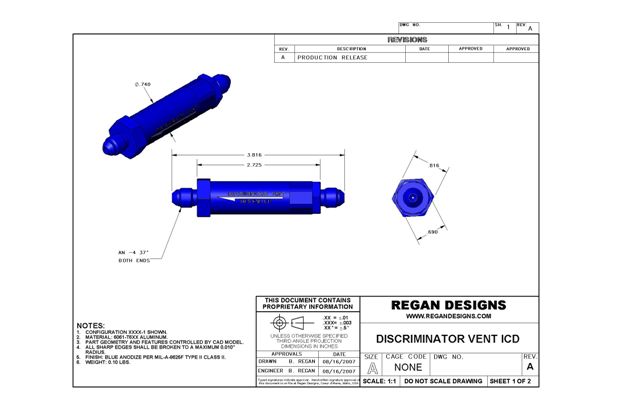

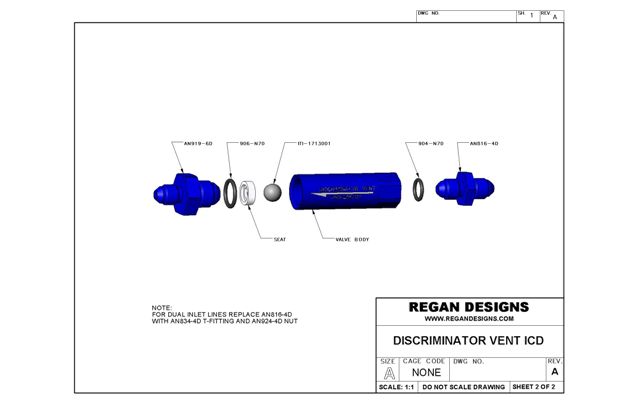

Ross sphere idea, I designed a check valve with a PTFE (Teflon) seat,

improved gas porting in a small package that uses

standard AN fittings. The attached pictures show the design. I built a

couple of prototypes to test to confirm performance. The axial passages

allow air to flow around the ball without lifting it off of its stop.

Air can flow through the valve at a rate of about 5 GPM without lifting

to ball onto the seat and closing the vent. A small coaxial hole

prevents the ball from hydraulically locking onto its lower stop.

Testing shows that the Discriminator Valve works as desired, closing at

the presence of fuel. A small (<3cc) amount of fuel may get past the

ball if the fuel has a lot of velocity when it reaches the valve or if

foaming has reduced the fuel density. I also tested with the valve

inverted to confirm that even a low flow rate would push the ball down

onto the seat. This is important if the aircraft comes to rest upside

down.

The Discriminator Vent would be mounted high on the firewall with its

discharge connected to a tube that would then discharge onto the

windscreen on the passenger side. This would alert the pilot if the

vent failed and fuel was venting overboard. The bottom fitting on the

vent can be replaced with a T fitting and nut to accommodate the two

belly tank vents. At least one of the lines must be routed entirely

below the height of the vent to prevent a fuel lock.

This vent will NOT work in systems where the gravity drain rate is less

than the engine consumption rate. In this case the engine can drain the

belly tank and suck air via the vent. See the preamble regarding the

need for qualification flow testing.

I have forwarded one of the prototypes, CAD models and drawings to Tim

at Lancair for his evaluation. If they agree that the design has merit

they will likely manufacture and supply the valve at a reasonable

price. The design is free to Lancair. I am doing this pro bono because

it takes me 2 days to analyze data and prepare an

accident investigation report for the NTSB. A task I do free of charge

and dislike immensely. It took me about 2 days to design, fabricate and

test this design so if it prevents one operator induced accident then

it is a break even deal for me. There is also that little thing about

not

notching another wreck.

Fly safe(r).

Regards

Brent Regan

Discriminator Prototype.JPG

discriminator section.jpg

discriminator vent icd s1.jpg

discriminator vent icd s2.jpg

discriminator.jpg

|

|