|

|

The question came up the other day as to what happens to fuel ,

specifically Jet-A, when it gets really cold. There has been some

debate as to if some recent turbine flameouts have been due to an

increase in viscosity due to the low temperatures at altitude followed

by a high demand during landing. Given that "one test is worth a

thousand expert opinions" I procured some Jet-A and performed a test

using one of the environmental chambers in our testing lab.

I used a one liter beaker with about 700 CC of Jet-A, a thermocouple

probe, a painters viscosity cup, a stop watch and the thermal chamber.

For comparison I also tested some Red Tractor Diesel (used by farm

equipment since it is sold without road tax). Viscosity was measured

by dipping the cup in the fuel then measuring the time it takes to run

out a hole in the bottom.

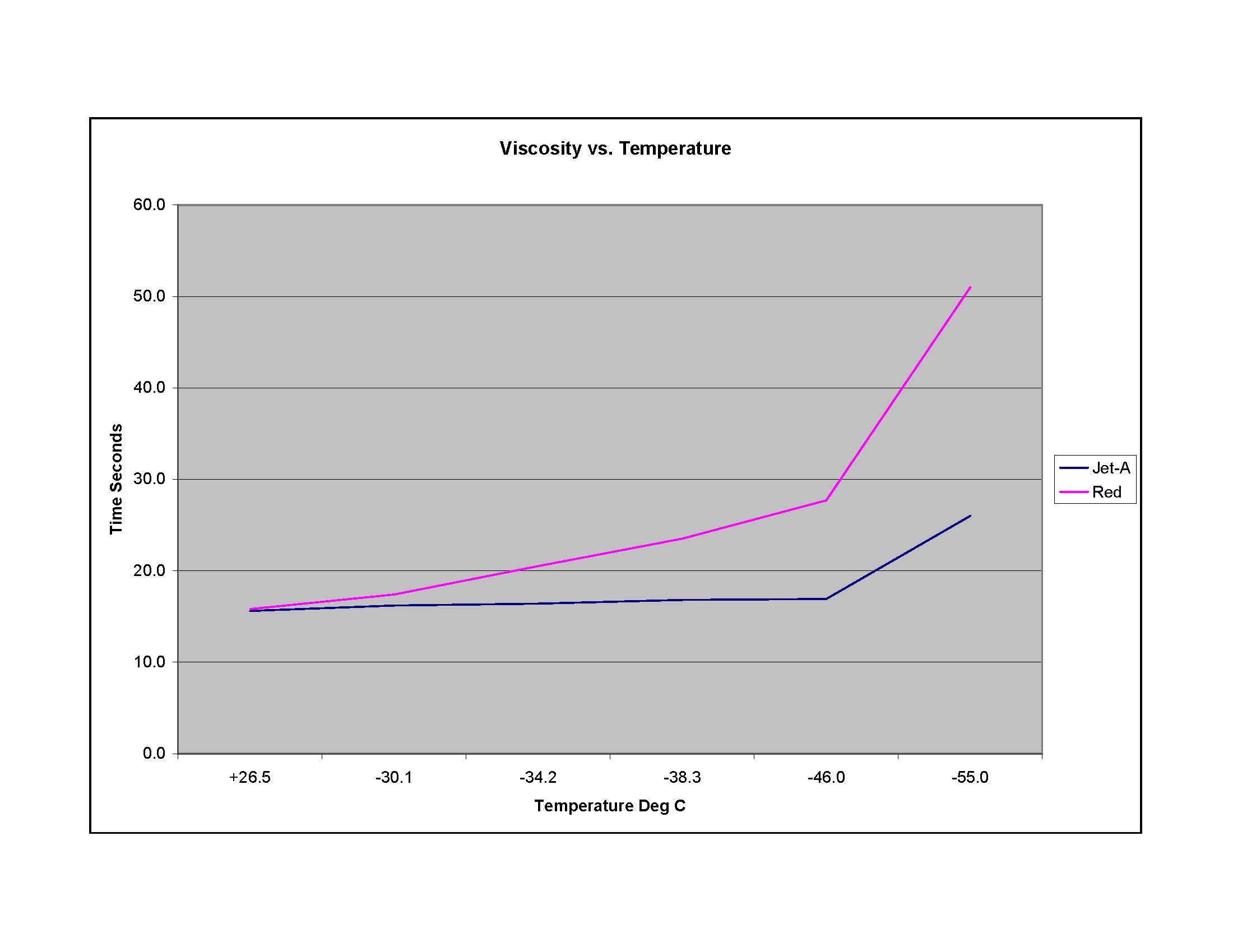

The results are as follows. Temperatures are in Celsius and time is in

seconds.

| Temp |

Jet-A |

Red |

| +26.5 |

15.6 |

15.8 |

| -30.1 |

16.2 |

17.4 |

| -34.2 |

16.4 |

20.5 |

| -38.3 |

16.8 |

23.5 |

| -46.0 |

16.9 |

27.7 |

| -55.0 |

26.0 |

51.0 |

| -69.0 |

Solid |

Solid |

It was interesting to note that the Jet-A maintained a consistent

viscosity down to a temperature you would expect to find at the

tropopause (~-50 - 55C). Due to RVSM limitations it is unlikely that

any homebuilt will be routinely operated above FL270 where IACO puts

the temperature at -38.4C. You would need a IACO -18C day at that

altitude and enough time to cold soak the fuel before viscosity became

an issue.

Temperature had a much larger effect on the Red Tractor Diesel. I

suspect that this is because the diesel is a much broader fraction of

the distillate.

The best part of the experiment was freezing the fuel. As you can see

in the pictures the Jet-A turns into a gelatinous Vaseline like solid.

In one of my less than brilliant "licking the flagpole" moments I

touched the surface of the frozen fuel, forgetting just how cold -69C

(-92F) is. Within a second the tissue on the tip of my finger was

frozen white and hurt like hell. Fortunately the years of jousting

with fellow engineers has given me a thick skin so no permanent damage

was done. As punishment I had to say the subject line of this post 5

times without error.

One other observation was that atmospheric moisture would condense and

freeze on the surface of the fuel. I could imagine that the warm wet

air entering a vent line during decent could condense on the interior

surfaces of the tank. A good reminder to check those sumps often!

The test suggests that for operations below FL270, fuel system flow

tests at ambient temperature are sufficient to qualify the delivery

rate of the system. If an alternate fuel is considered (e.g. Red

Diesel, Bio-Diesel, fry oil etc.) then additional flow capacity would

likely be needed. For example, the time required to drain a tank

(fuel bay) of Red Diesel at -38C is roughly 80% longer than at +26C so

the fuel system would need to be designed accordingly.

Regards

Brent Regan

DSCF3118.JPG

DSCF3119.JPG

DSCF3120.JPG

Jet-A Viscosity.jpg

|

|