15 minutes into a leisurely 50

minute return flight from across the border (WI/IL border) I experienced what

felt like a sledge hammer whacking the plane – A big misfire of old reliable up

front. Not to worry, once or twice

a year these things happen at night, over water or in the mountains – Slug of

water (I did top off in WI)? Fiberglass shard going thru an injector? Or just a

mysterious happenstance?

Now that I am alert, another

occurs, then another, etc. About 15

random times over the remainder of the trip – With my hand poised over the

“nearest airport” function, noting that at 5500 feet I had maybe an 8 mile

engine out range (there is a high airport density in this part of the country),

I repeatedly ran thru the engine/ignition instrumentation looking for anomalies

– none were noticed. I did reduce

power somewhat and the misfires seemed less “noisy.”

The investigation began the next

day after things cooled down, checking the obvious things first. Let’s see, no water in the fuel so the

cowl was pulled and the experimental injector air supply system was checked

for blockages. Then, the LSE timing

sensors (mag accessory gear driven) were examined and the right d-sub connecter

was LOOSE while the left one was not tight.

Hmmmmm……………………..

In a long-ago conversation with

Klaus, I noted that these connectors had loosened up after just a few test

flights and he had mentioned that some users had put a tie-wrap around the

connector to keep the hold-together screws from backing out and that the exiting

wire had to be supported to something that shook with the engine. So I did that. At OSH I talked again with Klaus and suggested

that if the Hall sensors had pig tails the connectors could be isolated from

vibration. He said “Yes, you can do

that.” There was no hint he would

ever change. Note that the LASAR

system uses very nice locking connectors at the end of a 10” pig tail.

Anyway, I was sure that the loose

connections I found could cause bad timing information and subsequent

misfires. I was not going to have

that happen again – especially since I had only 20 hours since these connections

were last secured with the tie wrap scheme.

So, I bought replacement metal

connector covers (Mouser Electronics) with stemmed hold downs that I drilled for

safety wire.

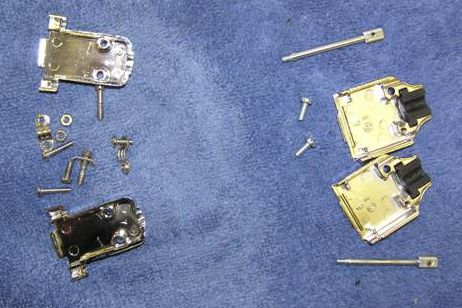

The one on the left is the LSE

supplied metalized plastic cover with wee hold down screws. When I disassembled it, even the cable

relief clamp had come loose. The

metal one on the right has different sized hard rubber relief clamps and, also

note the drilled thumb screws. Medium strength thread lock

(blue) was applied to the screws that hold the case halves together. Mouser's write up indicated that

metalized plastic covers had a 30 Db noise rejection rating whilst the metal

ones had a 70 Db rating, another positive.

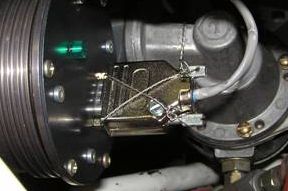

Here’s what the left one it

looks like with the thumbscrews safety wired in place:

Yesterday, a 1 hour test flight

went smoothly – no hiccups, no sledge hammers.

Scott Krueger

AKA Grayhawk

Lancair N92EX IO320 SB 89/96

Aurora, IL

(KARR)