Hello Legacy builders,

I’d sent

an earlier post asking if anyone had an improved modification to the Legacy's

canopy flexing problem that results with Lancair's

original hinge and gas spring strut design. The problem I see with the modification is

that the canopy strut torque runs out too early and it wants to fall when it

gets within about 30 degrees of being closed.

I haven't seen

any responses to the query -- so, I figured it was about time to give a little

back to this fine group that has already helped us so much. I’ve built a math model of the

basic mechanics to see if it could help us all understand more clearly what is

going on and how it might best be improved upon.

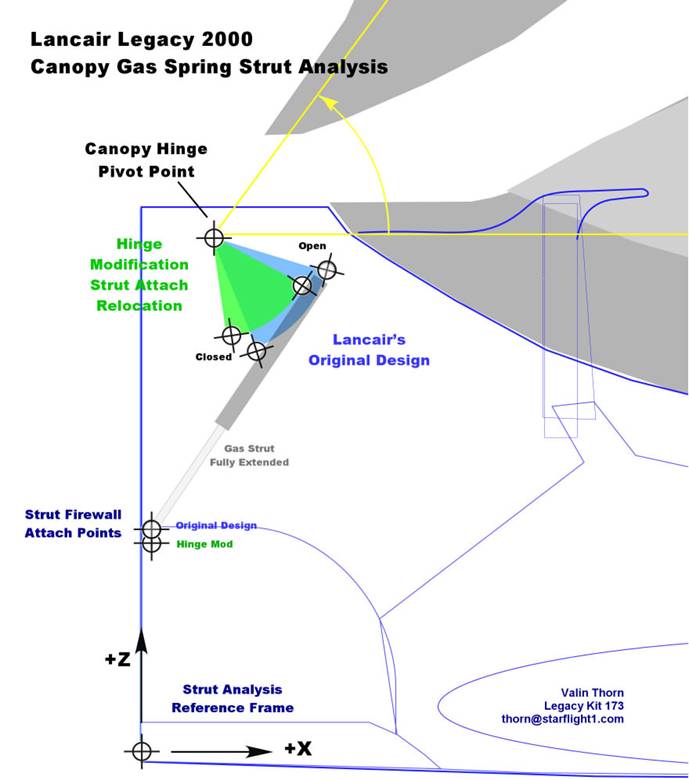

The drawing

below shows the basic geometry of the problem. The original Lancair design and hinge

modification geometries are shown (sorry I didn’t draw the actual hinge). The attach locations were accurately

measured, canopy weighed, and its center of gravity determined. The gas spring strut force profile vs.

compression was also determined by testing. Scroll down for the rest of the message.

Here is the torque

profile vs. canopy open angle of Lancair’s

original design. The red line is

the imbalance between the canopy closing torque from its own weight and the opening

torque from the gas spring struts.

Positive values are a net opening torque. Notice how there is positive opening

torque all the way down to only 5 degrees open.

Here is the torque

profile vs. canopy open angle for the hinge strut attach

point modification. The reason this

modification helps with the canopy flexing is that it takes out almost all of

the strut opening torque when it is closed. Notice how open angles less than 35

degrees don’t have enough torque to hold the canopy up. And, it falls off so fast that if left on

its own it slams down pretty hard. It

could even be a real safety hazard – I wouldn’t want anyone’s

hand or fingers on the fuselage opening when that happens. It also makes it harder to get the

canopy open since the pilot has to apply so much more force to get it going up.

This math model

confirmed what we’ve seen in testing the two canopy strut attachment

concepts. In the model, it was very

easy to play around with different attach locations (hinges and firewall) and

gas strut force profiles. I developed

another option that matches the original design torque profile very well with a

compressed strut force reduction of about 60 lbs (260 lbs vs

320 lbs for original design, 300 lbs for mod). It also requires new weaker struts. I’m pretty convinced that most of

the flexing is a function of the torque on the canopy hinge when closed and not

so much the direct force of the struts on the hinge transmitted to the canopy and

fuselage. This is because the two

struts in the mod are still combining for 300 lbs of force when the canopy is

closed – even though the torque is only about 800 in-lbs. I don’t think it would be worth

the trouble of getting new gas struts for the 60 lb reduction, in my candidate

mod.

Allyson and I

have decided the best option for us is to go with the original Lancair canopy

strut/hinge design and add reinforcement to the canopy to minimize the

flexing. We wish we had done the

reinforcement before closing the frame out with the skin… The hinge modification kit weighs almost

a half a pound (plates, bolts, nuts, washers: 6.6 oz) so we’ll just trade

that weight for some more BID in the right places. Then we’ll do more body work to get

it all nice and perfect looking.

I hope other

Legacy builders find this helpful. We’ve also decided on solutions for

opening the canopy and locking it. We’ll

send out a posting later in the week after we have some pictures and or

drawings.

Valin Thorn

Legacy Kit 173