|

|

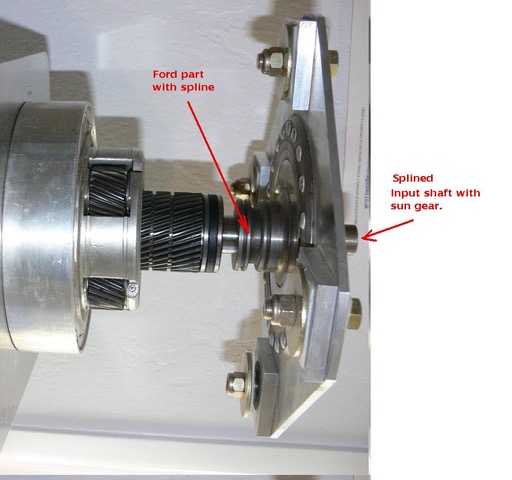

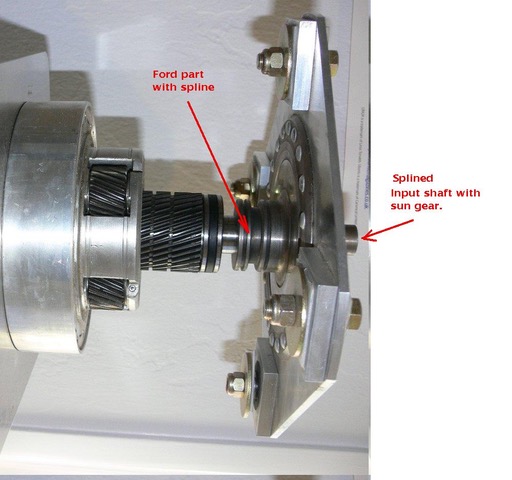

Another photo of the original assembly. Also, Neil Unger has done a good deal of work on isolators for his own drive assembly.

Steve

On 8 Dec 2024, at 7:29 am, Stephen Izett <stephen.izett@gmail.com> wrote:

Welcome David.

So if you have the original Input Shaft you would need to build what Tracy called the 'Hub Adapter’, obviously with the spine to match your ‘Input Shaft’.

Steve

On 8 Dec 2024, at 7:18 am, Stephen Izett stephen.izett@gmail.com <flyrotary@lancaironline.net> wrote:

Hi Guys

This is what I was able get from Tracy re his RD2 version without isolator.

His early explanation and drawings:

Cheers

Steve Izett

TRACY CROOK email re RD2 modification to remove damper Finally got around to flight testing the aftermarket flywheel setup for the RWS redrive.

The cracked flexplate issue some builders experienced came up at the same time as my CNC source for input shafts lost the ability to make them anymore due to loss of specialized spline making machinery. Since I had to line up a new source I took this opportunity to review the design from the input shaft back to the engine. Because the damper has been such an expensive and labor-intensive part, it was looked at as well. As a result, there have been enough changes to warrant a change in the name so the new drives will be RD-2B & RD-2C.

In rethinking the drive I had the thought that since the relatively low frequency primary resonance range of the drive train is taken care of by the system lash, that left only the high frequency harmonics that the damper is responsible for. This high range is the factor that creates the red zone in rpm ranges found on some certified engines and metal prop combinations. As far as I know, no one has used a metal prop on an RD-1x drive so I decided that it was an unneeded requirement. The new design has no damper at all and consequently it has a "No Metal Propeller" restriction.

Replacing the damper is a flanged spline that is bolted directly to the flywheel using the same bolts (longer bolts required) that attach the flywheel to the counterweight. The spline is a different spec (15 splines instead of 30) so it is not compatible with the RD-1 damper but the new shaft itself is backward compatible with the remainder of the drive. I retrofitted the same RD-1C that was on my RV-4 for these tests.

The flywheel was an aluminum racing flywheel with the replaceable iron friction surface unbolted and removed. Really looks pretty and professional compared to the flexplate. Any of the aftermarket RX-7 & RX-8 racing flywheels (steel or aluminum) that utilize the auto counterweight may be used.

As David Leonard found, these flywheels place the ring gear about .2" closer to the engine than the flexplate. To compensate, I milled .2" off the front surface of the adapter plate where the starter mounts. No changes were needed to the starter itself. I did not bother to grind the lead-in bevel on the ring gear teeth as discussed earlier. Starter engagement was smooth anyway.

The RV-4 drive had over 700 hours on it and everything looked beautiful inside. No signs of wear other than a shallow groove (~.002") on the input shaft where the 1mm thrust bearing race between the two needle bearings rides. Others have reported more than this in fewer hours so this is an area to inspect carefully. The new input shaft is a harder alloy (post machining through hardened 4340) than the the RD-1 which was pre hardened 4140. This should reduce the wear in this area. The old flexplate with over 1000 hours was still crack free. The input shaft oil seal still looked and felt new so it was not replaced as planed. Others have reported these leaking in much fewer hours. Don't know the reason but I suspect that oil temperatures out of range may be a factor. NEVER allow oil temps to exceed redline. If they go higher, back off the power then land and correct the cooling system.

Only 1 hour of flight testing so far but all indications were good. Operated the engine through the full range of rpm up to 7100 looking for telltale signs of resonance. I was sort of expecting to feel, sense or hear some indication of increased harshness in the drive with no rubber anywhere in the system but if anything, it felt smoother. There was none of the 'Waaa --- Waaa' warbling sound (like a twin engine with the engines out of sync) that I had with the Ross drive years ago. So far I'm very satisfied with the results but it's still early in the tests.

Tracy Crook

<RD2_HubAdapter.jpeg><RD2inputshaft.jpeg> On 7 Dec 2024, at 1:41 am, David Walker drw.aa@hotmail.com <flyrotary@lancaironline.net> wrote:

Hello,

New to the group, but longtime advocate and study of the rotary engine in Aviation.

I am building and RV-4 and thought I had a complete RWS redrive assembly.

Turns out I am missing the flywheel or ring gear and damper assembly that connects the redrive to the motor.

Does anyone have a spare? Or know how to fabricate this piece.

damper-shaft-sun-planet.jpeg

|

|