|

|

Lehanover@aol.com wrote:

> The racer idles at 2,200 RPM. Adjusting timing at just off idle can be

> misleading. At idle and close to idle there is nearly no cylinder

> filling, so the effective compression is very low, (say 5 to 1) so

> little heat of compression, low fuel supply, and poor flame propagation.

> Also the engine runs poorly when first started, but then runs fine when

> warm??

Lynn, I can't wait to fly down to Florida and let you play with this engine management system.

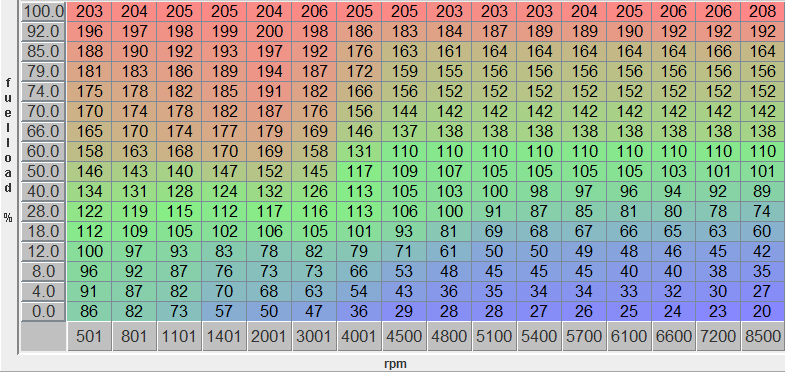

You start off by characterizing the injectors. You're telling the computer how many milliseconds to fire the injectors

for 100% VE. Then you modify a bunch of tables that have values for various RPM vs LOAD. Then there are a bunch of

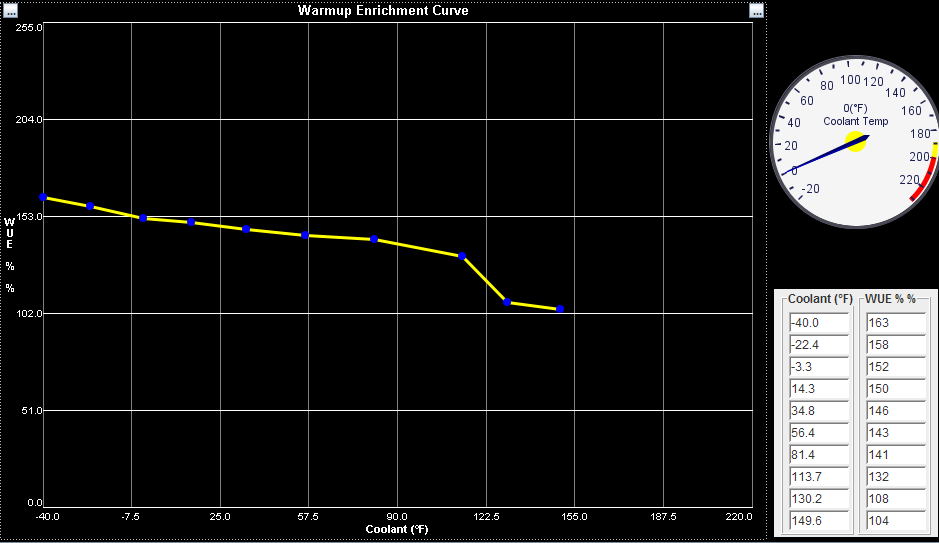

tables to modify the fuel for various other conditions. I have a warmup enrichment chart that adds a specified

percentage based on temperature. A chart that adds fuel for a number of cycles after startup, both the amount and

number of cycles based on temperature. There is a chart to add extra fuel during start...based on temperature.

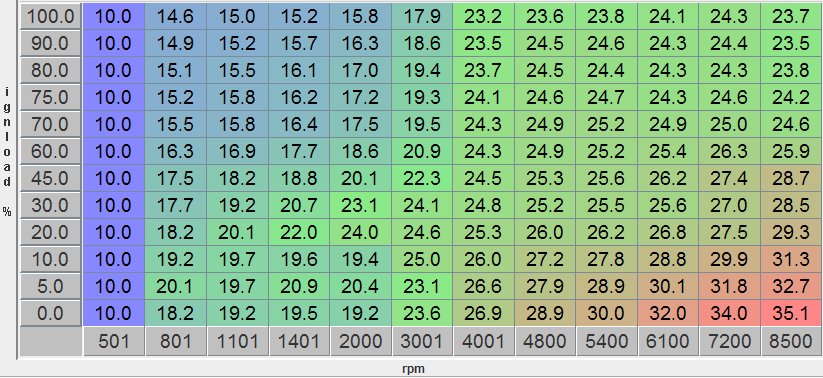

For ignition, there is a table to set the advance based on RPM and LOAD, and a chart to add advance based on temperature.

>

> Because better vaporization comes with rotor face temperatures and

> better more complete fuel burn and a bit more power. So typical

> controllers richen during cold coolant temps to compensate. Also advance

> my be reduced along with that temperature increase. Since there is so

> little fuel involved stresses are low and there is little chance of any

> kind of damage.

>

> To find out what is ideal for each condition I would keep advancing

> ignition as long as RPM keeps increasing. Then when RPM does not

> increase with the next change, back up three changes and make that a set

> point for that air temperature/coolant temp.

>

How big are your 'steps'?

I can adjust the timing in 0.1 degree increments. With the engine running and my laptop connected to the MegaSquirt, I

can hold the 'Q' key on my computer to continuously move the advance up or the W key to continuously move it down, all

while I'm watching the tachometer and it is all being recorded. Adjustments are easy and provide real-time feedback;

however, it's just like the old saying about tuning carbs. "The jet is $.50. Knowing which jet to use is $300." 8*)

> The problem is that beyond "just off idle" as you crack the throttle to

> begin to taxi, for example, the cylinder filling shoots way up close to

> 100%, so the effective compression ratio becomes 9.7 to 1 and your newly

> tuned in idle advance setting of say 27 degrees is now way too much

> advance for a slow turning engine with 100% cylinder filling.

>

> Perhaps 16, 18 or 20 degrees would be much better now and even then only

> with light loading. It is difficult to see but timing is based on RPM,

> and at low RPM you can achieve a complete fuel burn well before TDC and

> that would give you highest cylinder pressure well before 50 degrees

> ATDC. So if there is no system to pull out advance with sudden throttle

> opening, you are stuck with a lower fixed advance setting.

>

I've attached the fuel and ignition maps that I've been working with. They are not dialed in completely yet. I'm

working from the lower-left and getting it right there, I move toward the upper-right. What you see is fuel load (ie,

percentage of throttle open) vs RPM, and each cell contains the percentage of the 100% VE injector open time for that

condition, or the advance for that condition. I've also attached the warmup enrichment chart. For the temperature

along the bottom, the computer adds the specified percentage to what it gets from the fuel table.

Last night, I was running around 2000RPM with about 3% throttle. The base open time for stock 460cc injectors is

9.5msec. Picking up the fuel load from the table, that 9.5 is multiplied by 0.68. With the engine starting at outside

temperature, around 80*, that is going to have some warmup enrichment added, so the open time is multiplied by 1.41 from

the WUE curve. So the injectors have power applied for :

9.5*.68*1.41 = 9.1msec.

>From the ignition table, the advance is going to be set at around 19.8...the computer does a weighted interpolation

between cells when the RPM and load don't fall directly on a cell. So in this case, the advance is somewhere between

the value for 0% and 5% load and at 2000RPM.

If I had a sensor that could tell me at what point point I reached max cylinder pressure, I could dial this all in with

a couple of runs. (And, if I had some pixie dust, I wouldn't need a stupid airplane 8*)

FuelMap.png

IgnMap.png

WUE_Curve.png

|

|