|

|

|

Ed,

I've been trying to understand that for years -

Thanks.

George ( down under)

Ok,

Chris,

If you are going to

“blow” your rotary, ya gotta use the correct terminology {:>). The

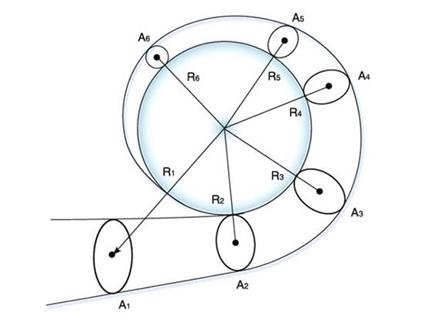

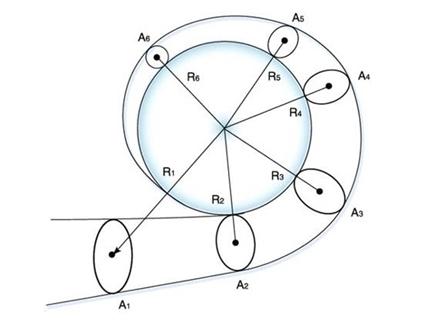

correct terminology is the a/R ratio or “ a R ratio” rather than “aspect ratio

– not bad” which is actually the ratio of the exhaust area of the

turbine outlet to the radius of the center of that area from the turbine

shaft. (see drawing below)

As you might imagine

the more “a” or area of your turbine exhaust compared to the radius of its

blades the more exhaust gas can “escape” around the blades without imparting

its full force. So with more “a” it takes more exhaust gas volume to

drive the blades to the same rpm. For a sports car feel, a small a/R

means the smaller area forces the exhaust gas to interact more with the blades

and gives you more Zoom at lower engine speeds. Whereas for aircraft use

you generally want more power at higher rpm (no need at lower rpm {:>))

therefore normally an a/R of around 1.0 or close to it is desired.

Depends on a lot of factors, but that’s it in a

nutshell.

Turbocharger Area

Ratio

A/R

The other consideration is the

A/R. It determines when the turbine starts to spool. The turbine housing A/R

is the cross sectional area of the turbine housing divided by the distance

from the center of that cross section to the center of the wheel. This makes

sense if you look at the graphic.

If you

take for example, the area in A1 and divide it by R1, you will have found the

A/R for this turbine housing. Each cross section and radius have the same

proportions so the A/R will be found by using any cross section/radius.

Common turbine housing A/R's are .58, .69, .81, .84, .96 and 1.00. The

turbine will start to spool sooner with a .58 A/R, and later with a 1.00 A/R.

Lag will be a problem if the A/R is too large, but if it's too small, the

turbo will run out of steam and be nothing more than a restriction.

If It works fine

for John, it should work fine for you.

Ed

From:

Rotary motors in aircraft

[mailto:flyrotary@lancaironline.net] On

Behalf Of Chris Barber

Sent: Thursday, May 27, 2010 6:27

PM

To: Rotary motors in aircraft

Subject: [FlyRotary] Re: Rotary HP

revisited

When I ordered my

prop from IVO I pretty much had them send me exactly what John had.

He actually said..."you want what John Slade has?" At the time, IIRC, it

was a 68" at the time so that is what I believe I currently

have.

I too have the 2.17

redrive. I hav yet to order the module from IVO for it to

regulate RPM. May do so soon.

I think you and I

have the same aspect ratio of 96 (?). My first start with the turbo was

with a six pound spring but on advice of a trusted friend who has more

experience, I replaced it with a three pound spring to start out with.

It was the three pound spring that I ran yesterday. We are thinking that

minor boost should be a better starting point and reduce potential problems.

Should we want more later and determine it is prudent, we can increase

it. The "Performance" wastegate comes with various springs that can

be used individually or in combination from as low as 1.5 lbs upt to 25

lbs + (I believe).

The wastegate

is located behind the turbo. See the attached photo. Since this

shot was taken about two weeks ago, I have replaced the blue oil line with a

stainless one with a 90 degree fitting. I have also fabricated and

installed an additional weight support to bear some of the load off of the

turbo manifold.

I will post more

pictures in separate emails so not go over size

limits.

From: Rotary motors in aircraft

[flyrotary@lancaironline.net] on behalf of John Slade

[jslade@canardaviation.com]

Sent: Thursday, May 27, 2010 9:40

AM

To: Rotary motors in aircraft

Subject: [FlyRotary] Re: Rotary HP

revisited

Hi Kelly,

My IVO is 66 (I found 68

gave too little ground clearance), 3 blade and the higher pitch.

Yes, it's

a 2.17.

Regards,

John

Kelly Troyer wrote:

What

is your "IVO" diameter, number of blades and are your blades the 30 to 90

or 45 to105 degree pitch ? If I

remember correctly you have the 2.17 to

1

RD1B gearbox.................

Kelly Troyer

"Dyke Delta"_13B ROTARY

Engine

"RWS"_RD1C/EC2/EM2

"Mistral"_Backplate/Oil Manifold

From: John Slade <jslade@canardaviation.com>

To: Rotary

motors in aircraft <flyrotary@lancaironline.net>

Sent: Thu, May 27, 2010 8:44:43

AM

Subject: [FlyRotary] Re:

Rotary HP reviisted....now that I know more about it

all...kinda.

Hi Ed, Chris,

That all makes sense, but I can add

something from experience with the IVO prop - The minimum pitch setting seems

to optimum for take-off power. When I changed from a big fixed pitch prop to

an IVO at minimum pitch the difference in acceleration was very marked. I have

never taken off with the pitch at a higher setting than minimum, so I can't

attest to the effect, but if you forget to put the pitch on full fine on the

downwind, a go-around is much less doable.

Something else about the

IVO that might help, Chris, is that when you throttle back on final the

airplane will want to slow down quite quickly. This is somewhat unexpected if

you're used to a fixed pitch prop that tends to make the airplane float on

final. The combination of fine pitch at idle, both rudders and the landing

brake make a Cozy (or Velocity I would think) come down like an elevator.

One way to check that you have enough power would be to measure how

much runway you use to reach, say, 70kts. If it's more than 2000' I'd say

you're under powered. With a turbo and an IVO the acceleration should feel

like a good sports car, and the increase from 70 kts to flying speed will only

take a few seconds.

My 2c.

John

to Ed Anderson wrote:

No easy answer – to

all the nuances of producing power, Chris.

200 HP is a

possibility depending on lots of factors (like your total induction system set

up, however, I believe that 180 HP is more in line with the likely maximum on

the older 13B. The Renesis a bit more/

Fuel flow is as much

an indication of power as anything short of a dyno and/or extensive aircraft

performance numbers.

RPM (in my

opinion) has too many variables – like I have a 74x88 prop with a 2.85:1

gearbox and can turn 6000-6200 rpm static – does that mean I am making

more or less HP than you at 6200 rpm at 35” Hg. It all depends on what

prop load each of our engines are seeing at that rpm. Generally as a

rough rule of thumb you can

figure 10 hp per gallon/hour of fuel flow. So it you have a fuel flow of

16 gallon/hour then your engine could be producing around 160 HP. 18 GPH

= 180 HP, etc. Now your power won’t be more than that, but it could be

less. The rotary can flow considerably more fuel without making useful

power than a piston engine, but it is a useful rule of

thumb.

I street ported my 91

Turbo block myself using a Mazdatrix street port template. I

went through 5 intake designs and several muffler experiments before finding

one that appear to give me the power I wanted. On a cold morning with

OAT < 50F, I can get up to 6200 rpm and 18-20 GPH fuel flow with the 74x88

prop. So I feel I have my set up just about as good as its going to get

– short of a forced induction system.

With your prop set at

max fine pitch, you have reduced the prop load on your engine to a

minimum – that permits your rpm to be at a maximum – but, that does NOT mean you are producing the power and

more importantly - the thrust

needed for safe flight.

Don’t be

mislead by rpm. As an extreme example to make my point, Without a prop (almost no load) my engine

will turn 5500 rpm at idle throttle setting – but I am only flowing something

like 1.5 – 2 GPH which means producing something like 15-20 HP even though the

rpm without prop is higher than my static was when I had my old 68x72 with a

2.17:1 gear box. So even though the rpm is the same or slightly

greater, the engine not making any where near the 150-160 HP I made with

the prop on at the same rpm. Fuel flow is not a perfect indicator but

much more useful than RPM alone in estimating your power particularly with a

variable pitch prop.

This is important,

Chris. Years ago, there was a long EZ builder who had a non-rotary auto

engine who unfortunately ended his first flight in a fatal crash into a cactus

plant. He understood the electronics just fine, but did not understand

the relationship between rpm and thrust. He set his adjustable pitch

prop for maximum RPM – which

mean minimum prop load, which in

his case mean minimum

thrust. He managed to get airborne with this limited thrust,

but could not apparently climb out of ground effect with the flight ending on

impact with a cactus.

For example,

you would get your highest rpm with a prop that absolutely no pitch which

would produce minimum load on the engine – however, I think you would agree

there would not be much “push/Pull” by such a prop set up. With a

variable pitch prop, you need to find the optimum balance between rpm and

thrust. Too much rpm could indicate too little pitch (and too little

thrust), too low rpm could indicate too much pitch (and too little thrust) –

neither condition gives you maximum thrust.

The only way I can

think of to find that optimum balance between rpm and thrust is to attach your

airframe through a scale to an anchor. Then measure the pull on the

scale at various rpm and prop pitch settings. This should help you find

where combination of engine rpm and prop pitch provides maximum thrust (at

least maximum static thrust – which is a good start). Perhaps someone

else can offer a better and easier method. Yes, you should be able to

get a feel during taxi test – although some folks frown on the idea of

high-speed taxi test. Theoretically you could use an accelerometer, some

accurate speed measurements the weight of your aircraft and calculate

the effective HP – that has been done with automobiles.

In cases were folks

are using fixed pitch props with parameters similar to those used by

others, you can make a comparison and get a rough feel for engine performance

based on RPM. Unfortunately, with a variable pitch prop making such

comparisons is more difficult and questionable. Now if you can find

someone using the same variable pitch prop you are using and compare your rpm

and prop settings, that is certainly something worth checking

into.

Just continue to ask

these kinds of questions and to think about the issues in producing power and

thrust – you’ll be ready.

Ed

.

From: Rotary motors in aircraft [mailto:flyrotary@lancaironline.net] On Behalf Of Chris Barber

Sent: Wednesday, May 26, 2010 9:51

PM

To: Rotary motors in aircraft

Subject: [FlyRotary] Rotary HP

reviisted....now that I know more about it all...kinda.

I know this must

have been discussed, but perhaps more in passing or in some of Tracy 's literature

(now kinda dated, especially with some of the strides he continues to

make), but what is the conventional wisdom as to rotary horsepower? I

know when I first started looking into it, oh many years ago, it seemed the

impression I got was that you could pretty easily achieve 200 hp, however,

that is now a bit lower. Some of the tricks to get the higher HP was

mild and medium porting, bridge, "J" and "P" porting. Then there was the

option of turbo...the one, in combination with a medium street port, I

chose.

When started today,

mine was turning about 6200 rpm at 35 MP (with a 3 lb spring in the

wastegate).....it surged forward against the chocks and breaks. IVO

prop full fine. Nice feel of power even if it likes to heat up fast in 90

degree weather like this.

Also, I think this

was discussed before too, when I go WOT my engine develops up to

about 6250 rpm, but then drops a couple/few hundred rpm to usually just under

6000....sometimes just above. Thoughts? Ed, (perhaps Al)it seems

you may have chimed in before. Regrettably, when I search

the archives I tend to get frustrated due to thread

drift.

I heard a lot about

porting when I was initially investigating all this and I chose to use a

medium street port. I let Mazdatrix do the work. That being

said, I have read all but nothing on others porting their engines (other than

a LOT from PL on P ports). Since

standard porting does not reportedly effect reliability, only, potentially

low low idle (I can idle as low as about 1300 rpm when warm smoothly) why

is it not discussed and/or utilized more?

Just curious

guys/gals. Discuss <g>

Always loved the

lines of a Tailwind – in fact, I have the plans and license to build a W-10

sitting on my book shelf. Unfortunately, I doubt I’ll ever get around to

it.

Ok with thermostat in

the system holding it at 190F – we really won’t know how much reserve capacity

you have in your cooling system until the power goes up.

I agree with George,

200HP out of an N/A 13B is really pushing it. I think 180HP is a more

realistic expectation – but, hey you never know. It amazing how power

goes up when things come together.

Enjoy and fly safe.

From: Rotary motors in aircraft [mailto:flyrotary@lancaironline.net] On Behalf Of John

Sent: Wednesday, May 26, 2010 2:36

PM

To: Rotary motors in aircraft

Subject: [FlyRotary] Emailing: 3 view

w-10 003, first flight

My most humble thank

you to flyrotary and all you fine folks that have helped bring my

project to flight. Ed and many others whom I won't try to name here

because I would miss many. The plane is a Wittman Tailwind W-10, empty

wt. is 981 and it is a tri-gear, Wt. is within 6 #'s of similar trikes

w/ 0-320 engines. I have the thermostat in the engine because most of

the year it is not very hot, if we get 50 days with the temperature over 70,

we have had a hot summer, not a lot of beach bunny activity. 7-1 I'll be

74 and have realized my dream, now it's all gravy. Again, thanks

guys!! JohnD

Your message is

ready to be sent with the following file or link attachments:

3 view w-10

003

-- Homepage: http://www.flyrotary.com/ Archive and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html

-- Homepage: http://www.flyrotary.com/ Archive and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html

image001.jpg

|

|