Here’s a correction to the Medeco

cam lock part numbers I’d provided earlier and additional installation

instructions. The part numbers are still

different than what we’d ordered while developing this concept –

but, this is what we’d order today after all we’ve learned. Hope this is more helpful…

Valin

--------------------------------------------------------------------------------------------------

Here’s how Allyson and I set up to lock our Legacy’s

canopy…

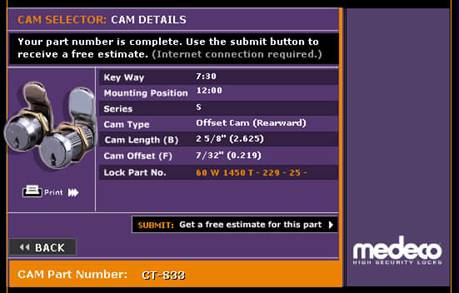

First, we purchased this Medeco high

security cam lock:

Here are the Medeco lock’s

specifications:

This Medeco Cam Lock can be ordered from the RA-Lock Company of Cedar Hill, Texas (800.777.6310). The lock is $23.25, the

cam is $0.59, and the keys are $1.75 each.

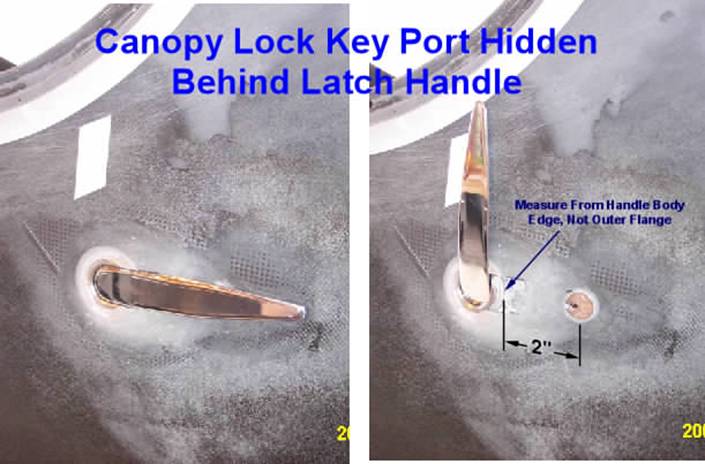

We placed the

cam lock just behind the latch handle assembly.

This allows us

to hide the key hole behind the latch handle when in the normal latch handle

position.

With the

canopy latch handle in its normal aft trailing position, trace its outline onto

the fuselage skin with a marker pen.

Draw a horizontal line down the center.

Measure two inches from the latch handle body edge and mark the center

of the hole for the lock. Drill a

¾” hole for the cam lock at this location. This hole is big enough for the body but not

the head of the lock. Place the lock in

this hole with the head against the fuselage skin and draw a circle around the

head. Grind away the outer skin of the

fuselage to this line so that the cam lock rests flush with the outer

skin. De-core about a half inch into the

fuselage skin around the lock head. This

area will eventually be filled with epoxy/flox

mixture for final bonding.

We built a strong fuselage housing for the lock out of ¼” thick

phenolic. The body of the lock has two flat

sides that need to be firmly against phenolic sheet

to ensure that the entire lock housing can not be forced to rotate. The phenolic

housing sides are basically one inch square pieces and the flanges are 45 deg

triangles with one inch sides.

The lock

head face should be bonded in flush with the fuselage skin. Tape over the key hole to ensure no epoxy/flox enters during bonding.

We put the fuselage on its left side for this so that gravity was more

helpful and duct-taped a piece of wood against the hole on the outside to

provide a platform to rest the lock on and ensure it was perfectly flush with

the fuselage skin.

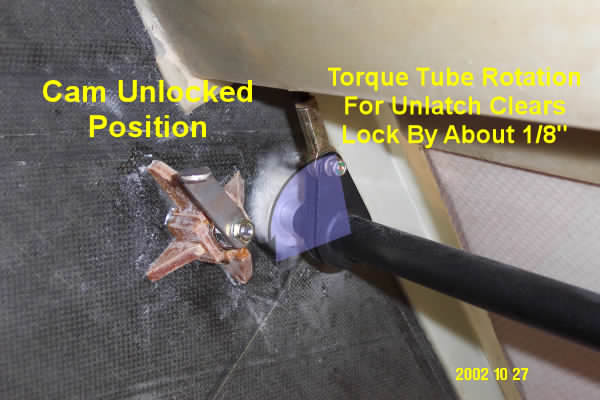

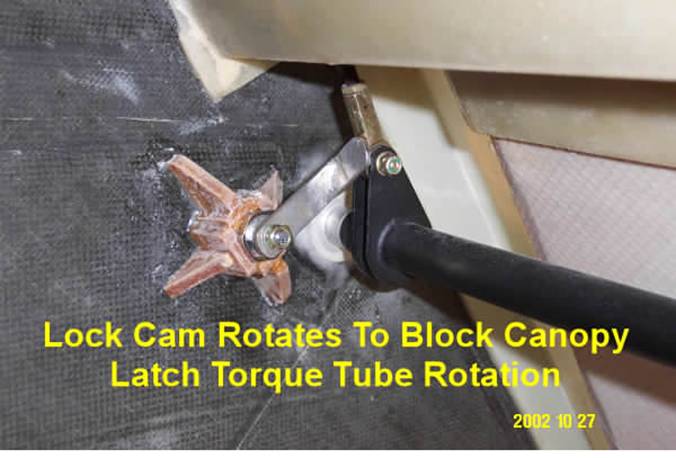

Before

bonding it all in, hold the lock with the cam in position to ensure that the

rotational orientation for locked and unlocked positions is correct and that

the cam has been bent to the correct shape.

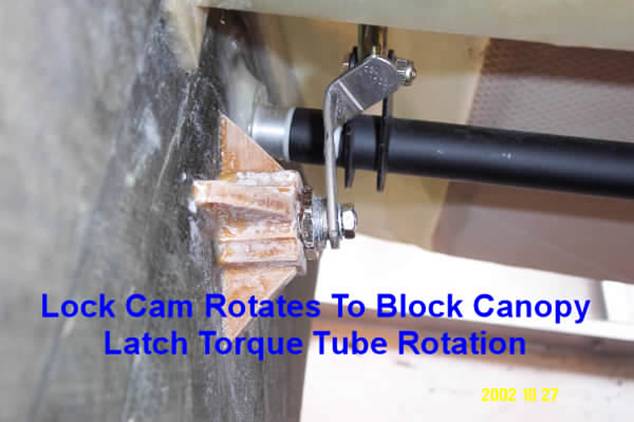

We hammered the

cam out straight and then bent it about two inches from the attached end to get

the right geometry to block the canopy latch torque tube.

The key hole slot should be approximately vertical and at the bottom for

the locked position and horizontal and on the left side for the unlocked

position.

Bond

everything in place with an epoxy/flox mixture. Be sure to tape over everything you

don’t want epoxy on.

We’re

pretty happy with this solution.

It’s simple, light weight, and the key hole doesn’t show.

Valin Thorn

Legacy #173