|

|

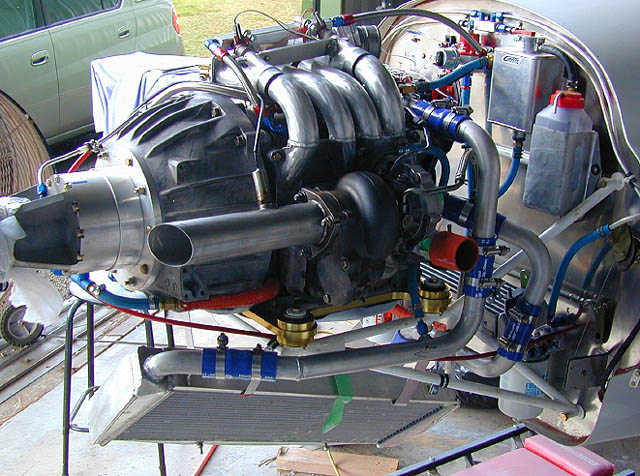

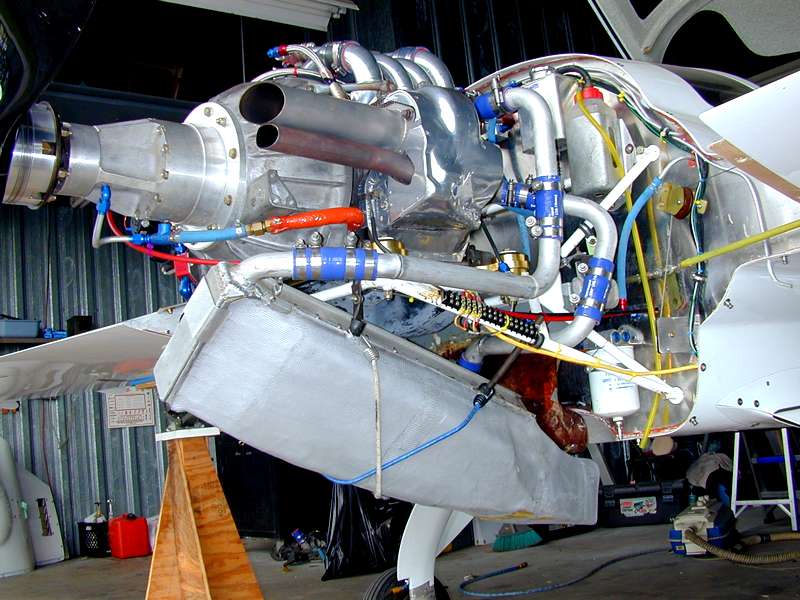

See the attached pictures of the engine and radiator I have from Buly as it was when installed in his Cozy. I have his radiator and ducting to the radiator. Not sure if this is going to be ample or not or if I should go bigger on the radiator? Any thoughts? I have stock inter cooler which I may use, but contemplating going to a more efficient unit.

As I read, maybe it was just an over site and you thought both were oil coolers at first, but then found out that one was a trans cooler. I would guess that they are both of similar size and cooling capacity.

I take it when you talk about the exhaust augmented cooling this is a vacuum created through the exhaust shield that the exhaust passes though from the prop and or exhaust flow to aid in air flow through the engine cowling / engine compartment and across all heat exchangers. Just thinking of adding a supplemental cooling fan to be able to utilize during ground operation in our 100 degree 100 percent humidity we can get. I don't know if I will have room to get it under the cowl or not, but we will see. I am still a little way from mounting the engine, but want to get started and get things planned out.

Wow, the standard NACA scoop is working that well for you. Glad to hear that. I guess Buly's huge scoop was a little bit over kill.

Not sure why they wouldn't have a proven turbo with the ceramic bearing. Just seems like that would handle much more heat. I guess the only concern is if the ceramic flaked off of the bearings. Ceramic coatings make very good sense as these coatings have been used in coating pistons, valves, etc... to help keep the heat where it needs to be and to keep it away from where you don't want it. It is and has been my thought that it is always better to learn from others mistakes and try not to repeat them. So starting from a proven setup, turbo or otherwise is the best way to go.

I will have to contact AGP and see what they can tell me about the other options. I am not sure what they are options for. I guess this shows how little I know about turbos.

I still need to get down to visit Chris and maybe check out his engine especially if it has to be torn down. Thank you very much for the invitation to come visit and really get a hands on view of your plane. I may have to take you up on that once the weather warms up. :) I sure would love to put my eyes on your plane. Pictures can only show you so much. A hands on sure makes a difference.

John, just a note to you and every one on the list. I really appreciate all of the work that you and every one has done to get things this far. It is nice to have a place where we can get problems figured out in a hurry and run our questions by someone that has been there and done that.

David Moyer

John Slade wrote:

David,

Yes, your 3rd gen Cosmo will need better cooling because it packs another 20 or 30 horses at least. I've seen those intakes - they're about 20% bigger than mine. I believe it's the same setup as mine - 3mm seals and 9.7 rotors. With a T04 it's gonna be a rocket ship. I think those 3mm seals will protect you from the detonation devil to some extent. I also found that the IVO prop kept detonation at bay. I'd hear it with my fixed pitch prop as the engine tried to turn it during run-up - kinda like using full throttle in top gear up a hill - but I never hear it with the IVO on fine pitch.

I slightly misspoke - One of my "oil coolers" is actually a 3rd gen transmission fluid cooler. They're almost exactly the same as the oil coolers.

I tried a very powerful coolant fan on the bottom of the rad (out of a Ferrari). It did nothing useful, and I think it got in the way of airflow when airborne. I took it out. Part of the problem may have been airflow when on. It could have been drawing hot air from inside the cowl through the oil coolers and recirculating it. I think the two most effective aspects of my cooling are the sealed plenum under the rad, and the exhaust augmentation. The latter handles on-the-ground cooling fairly well. I stabilize at around 200 on a hot day. I have a standard NACA scoop and no additional armpit scoops. I throttle back and do a "cooling pattern" after take off on a very hot 90F+ day. This seems to be a fair trade-off for minimum drag at altitude.

I installed a cowl flap at the back of the plenum. I can open it in flight to allow excess cooling air out of the back pf the boat tail cowl. I can't say for sure, but it doesn't seem to make much difference.

No, I didn't go with the ceramic bearing (on advise from the turbo expert I consulted with). He felt the standard bearings with the big shaft were more proven.

>What about the turbine wheel F1 62, 65 or 68?

No idea. I don't have a note of this option. I guess you could ask them what I got. Perhaps Chrissie knows. All I know is that it's T04E-50 big shaft tangential with P trim and wet housing. Does my aspect ratio of 0.96 tell you this.

>What about compressor trim 50 (2.122/3.000) or the Super 50 (2.122/3.200)?

Same as above

>Are you still running a stock intercooler or did you end up upgrading?

Stock, but the airflow to it isn't enough. My intake temps are too high. (130F or so). I haven't changed it because it seems to work as is. (ie I havent blown the engine up yet).

One suggestion I'd make is to do as I did and visit people who have running rotaries in Cozys, wherever they are. (Anyone except Chris :) - There's no comparison to one-on-one discussion and personal inspection of a working system at this stage. I was lucky - Greg Richter was just up the road from me and Buly was 20 miles away. Ride an aluminum tube to the North East and I'd be happy to provide accommodation / tour / experience flight.

Regards,

John

-- Homepage: http://www.flyrotary.com/

Archive and UnSub: http://mail.lancaironline.net:81/lists/flyrotary/List.html

1Engine11-04_sm.jpg

Engine734.jpg

|

|