|

|

On Sunday, January 16, 2005, at 11:29 AM, Russell Duffy wrote:

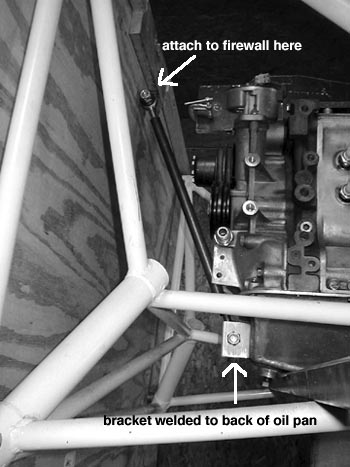

The S-beam mount only supports the front of the

engine. The rear engine support is provided by a adjustable strut

that runs from "someplace" on the back of the engine to "someplace" on

the firewall.

Hi Jerry,

Can you post a picture that shows an example or two of an "adjustable strut". As pictured, it looks like there would still be quite a bit of weight on the rear of the engine, so the strut can't just be a trivial piece. Goodness knows that if this evolved on the other list, it's been engineered way beyond my tolerance, but I just can't quite picture what you have in mind for the rear support.

Doesn't Atkins also use a beam system like this? I seem to recall that he used to sell the beams, but you were on your own to make the mount. Could be wrong about that.

Cheers,

Rusty (hanger roof is fixed, no more raining in the hanger)

Rusty, I took the attached photo of my engine today. Unfortunately the engine is not on the airplane but on a stand and the strut is not hooked up. The engine is temporarily supported by a piece of square tubing slipped under the pan. I think you can get the idea of how the strut works however. If we can get Bill Schertz to send a photo of his strut you would see a completely different way of doing it.

The strut has rubber cushioned rod ends, left and right hand threaded and acts like a turn buckle. The engine's pitch can be fine tuned by rotating the strut.

The idea was pioneered by Questair so we are going into unfamiliar territory. Jerry

Strut attachment.jpg

|

|