|

|

I installed the "rebuilt" Oildyne pump in its new home today on the

front of the baggage bulkhead and it seems to be working

just fine so far (knock on fiberglass). I still have some pressure

decay tests to run and have yet to adjust the pressure switches, but

the pump puts out pressure in both directions, the relief valves are

set, the system is bled, the gauges work, and the landing gear go up

and down. Life is good!

Rebuilding the pump turned out to be no big deal. The main thing I

would advise it that when taking things apart, don't let the

internal springs and ball bearings - especially the ball bearings -

go bouncing across the shop floor; Disassemble the pump on a cookie

sheet or something. "Rebuilding" consists of just changing all the

O-rings, the poppet valves and springs, the suction screens, and the

grease seal between the pump and motor. On my ancient pump there

were only five O-rings to change plus two more for the new plastic

reservoir. None of the 28 y.o. O-rings or seals looked deteriorated

at all, but I changed them anyway. (I used Parker O-lube to install

the new O-rings). Also, there's a plastic (or rubber?) coupling

between the motor and pump which should be greased. You need to

remove the motor to grease the top side but, again, no big deal...

The check valve (poppet) bodies and spool piece should be gently

tapped out with a drift and small hammer after removing both 7/8"

hex nuts on either side.

After reassembly, with the reservoir empty, I first primed the pump

by adding fluid to a 12" piece of tygon tubing that slipped tightly

over the -4 AN outlet fittings. I squeezed the tubing a few times to

work out the air bubbles, and looked in the bottom of the empty tank

for any drips which would have indicated a leaking suction

ball-check valve. I did this on both the HP and LP sides with no

leakage noted. (There's supposed to be some "official" priming

procedure, but I don't have a copy.)

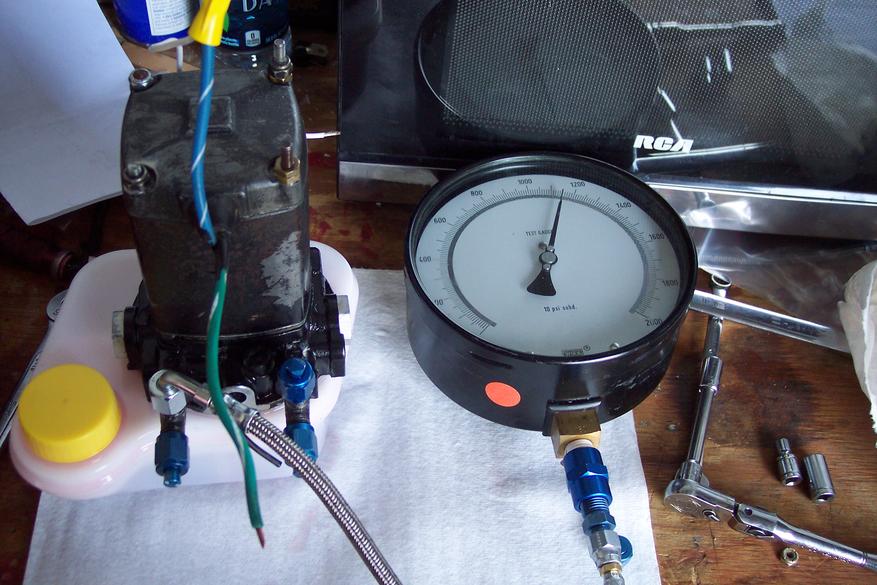

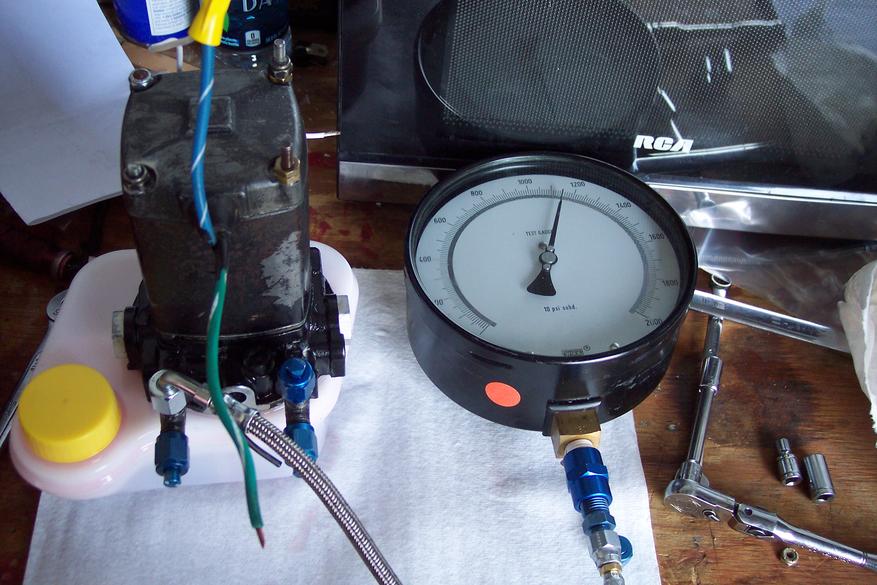

After filling the tank midway between the MIN and MAX lines, I ran

the pump "dead-headed" to check the relief valve settings. The pump

sounded good. The LP relief valve cracked at 800 PSI, which is

perfect, I think. The HP relief valve also cracked at 800 PSI - too

low - so I had to drain the tank and adjust that side. I turned the

valve 1 turn clockwise and re-ran the test but got 1,800 PSI that

time, so the factory "600 PSI per turn" wasn't really correct for

me. I backed off two flats on the relief valve and obtained the

desired 1,400 PSI. (Disregard the pressure reading in the photo

below.)

AFt AFt

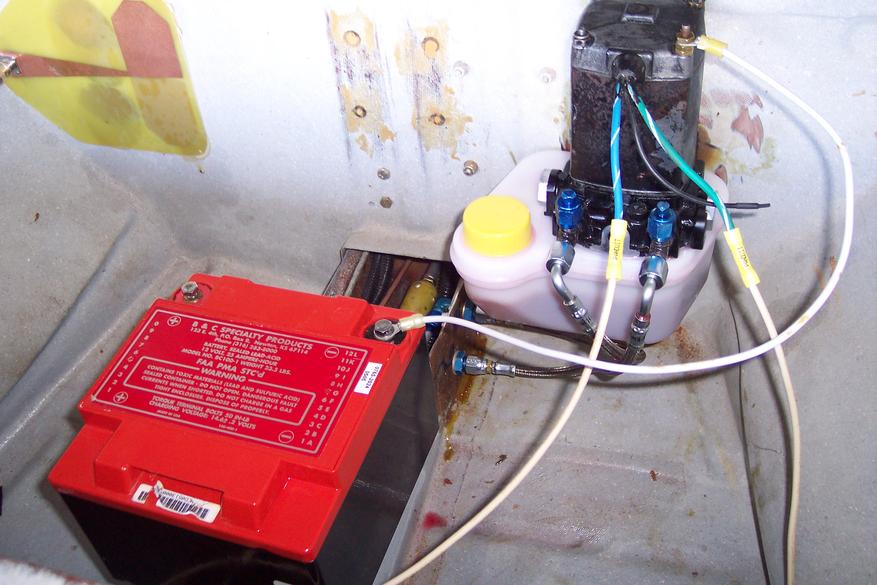

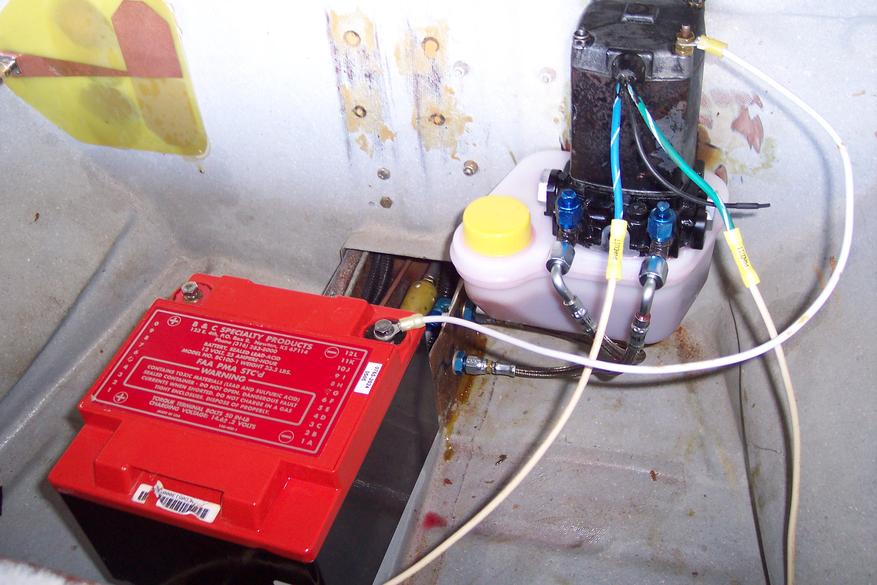

After mounting the pump on the baggage bulkhead, I pressurized and

bled the entire system one landing gear at a time (and bathed myself

in MIL-5606H in the process). I did the low pressure (DN) side

first, then the high pressure (UP). I used my old battery to run the

pump until I splice the wiring to the existing relays which I intend

to leave back in the trunk. I'm taking that long flexhose back to

the hose shop to have it shortened for aesthetic purposes. (That's

the transponder antenna in the upper-left, if anybody was

wondering):

I discovered today that the 2000 PSI gauge I recently bought from

McMaster-Carr had a manufacturing defect - the pressure port was

plugged with a piece of brass. When I originally installed the gauge

I thought that plug was some kind of OHSA safety device or

something, but that turned out not to be the case. I had to drill it

and remove it with an EZ-out. Weird...

I left pressure on the LP side overnight to check for pressure

decay.

Transformed_Lancair hydraulic pump reinstallation 001.JPG

Transformed_Lancair hydraulic pump reinstallation 004.JPG

Transformed_Lancair hydraulic pump reinstallation 003.JPG

|

|