|

|

|

Bill,

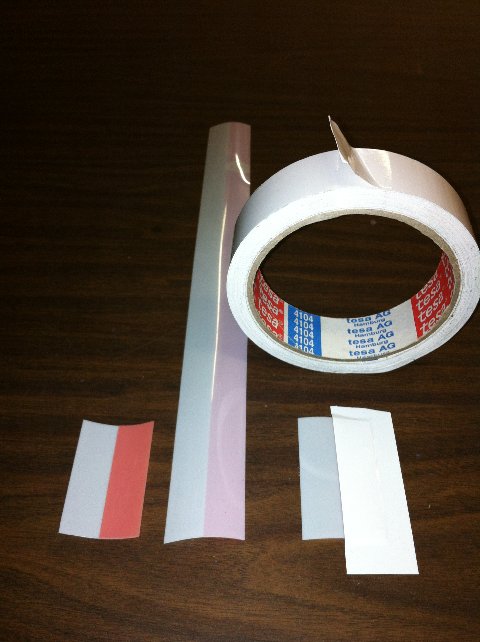

Here are the pix... The one below is of the material - Curved Mylar tape

with glue under the red peel off, top side of Mylar tape and leading edge safety

tape (very thin, very strong) plus the mfr info (TESA 4104 tape).

The Mylat is about 1.1" wide. Wider tape is used on the rudder.

The next pic is gap tape on the upper skin ahead of the aileron

If you want more I've got it.....

Scott

In a message dated 4/18/2012 10:01:20 A.M. Central Daylight Time,

bbradburry@bellsouth.net writes:

Scott,

Do you have pictures

of your gap seals? How are they attached?

Bill

B

From:

Lancair Mailing List

[mailto:lml@lancaironline.net] On Behalf Of

Sky2high@aol.com

Sent: Tuesday, April 17, 2012 9:52

AM

To:

lml@lancaironline.net

Subject: [LML] Re: L320 flap

setting

There must be as

many different ways to fly these airplanes as there are different wee

Lancairs. The techniques I use work for me, but there are other pilots

that use totally different methods with respect to flap management. I

tend to use distances, altitudes and speeds that would be similar to GPS

instrument approaches. From about 10 NM out I will slow to 160 KIAS

merely by reducing power and nearing a safe maneuvering altitude. Over

the next 5 NM the flaps are moved in 2 steps to down about 7 degrees (from

full up), level flight is then stabilized at around 120 KIAS. For the

next 3 miles, I descend to about 1100 AGL with power set to 15-17"

MAP. Depending on the type of pattern entry and with about 3 miles to

fly (downwind entry or straight in), flaps are brought down another few

degrees, gear is extended and speed is stabilized at about 100

KIAS. Descent is then managed so that when field is made, flaps

usually go to full down and power is controlled so that the

over the fence speed is also about 85 KIAS. I am not sure of the

other speeds as I am looking outside, but it seems touch down is at about 70

Kts since the round out also reduces speed and throttle reduction finishes it

off. The runway I generally use is 6500 feet, but the exit I

use is 2450 feet from the landing end (I see your runway is 2300

feet long) with very little braking. If there is a good crosswind I will

land with less flaps.

My flap is marked so

that all take offs are at 10 degrees down and lift off is at about 80

KIAS although the stick is pulled back to lighten the load and gain better

directional control as 40 knots is passed. I start every takeoff

run with the elevator trimmed to the same neutral position and I think I never

could fly off the runway without gradually pulling back on the

stick. Every pre take off configuration is the same so that

conditions different from the norm are under pilot control. For me,

the most efficient climb out is at about 135 KIAS for good

cooling and a very good climb rate while escaping the airport environment

quickly.

Since I enter the

"pattern" at no more than 120 KIAS, gear extension on a downwind takes

the speed down quickly. I do not fly the killer square pattern -

downwind to final is accomplished in a continuous turn so that any adjustment

for runway alignment can be made throughout the turn and not as a

correction to an already tight 90 turn from base to final. I do not fly

"close in" patterns.

My airport is at 700

MSL and I can understand your adjustments for altitude, shear, slope and

runway length. I know several pilots that are happier landing with no

more than 30 degrees of flap.

I have glider type

gap seals on the bottom of the flaps, and both sides of all other control

surfaces. Speeds increased by about 6-8 KIAS. Rudder control

became effective about 5 Kts sooner than before the seals. It becomes

more difficult to go down and slow down at the same

time.

In a message dated

4/16/2012 7:56:05 P.M. Central Daylight Time, lancair@meier.cc

writes:

this is very

interesting!

Could you write

down some more flap positions which you use for take off and landing in

different take-off weight configurations.

And also when you

arrive in the landing-circuit in cruise speed. How best to slow down to flap

speed in the downwind.

Actually when I

arrive from cruise, I put the engine to idle pull nose up to reach 120kt

drop gear, set flaps to +10 (17 from full

reflex)

and drop

nose and put back low power setting. After all this I get my 100kt and

turn to base leg. In final I use +20 / +25 and will also

land

in this setting.

My runway is 700m long and has a 1% down slope and is located in 2200ft alt.

If I use more flaps to land the plane won't sit

down.

Speed over the

fence is 90-85kts because of shear winds just before the

runway...

What speeds do you

use in short final?

Does it help to

stick some gap seals over the hinges of flap and aileron like all the

gliders do?

The purpose of

reflexed flaps (wing TE) is for reduction of drag at cruise

speeds. After certain minimum speeds, induced drag is lessened by

reducing lift through a reflexed TE (also reducing anti

lift at the horiz stab). Parasitic drag in a laminar flow

environment may also be reduced by reattaching the airflow at the

reflexed flap. The basic fat wing design helps when the leading

edge gets dirty (disrupts laminar flow) because lift is only slightly

reduced but draq increases (ice, rain, bugs - see note 1). This is as

opposed to a thin laminar wing which may lose lift when dirty. The fat

wings allows our grocery cart wheels to be stowed within.

When the flap is

reflexed, the point of lift moves forward where higher speeds require more

nose down trim (less negative AOA at the horiz stab) and lower speeds

require a higher angle of attack to achieve adequate lift. In general,

below a max Vf (160 to 140 KIAS), the flaps may be taken out of reflex

(to 0 degrees) where the attitude of the airplane can be changed

by up to 6 degrees nose down (as measured digitally at the

longeron) and this will require substantial nose up trim for level flight

while the speed drops (about 15 KIAS) from increased drag. For this

wing, further reflexing beyond -7 has little effect on speed in

cruise (Note 2).

This form of wing

is not unique - reflexed trailing edges are used in all tailless (and

non-canard) aircraft. In such aircraft, changes in CG are compensated

for by changing the angle of reflex (changes fwd/aft point of lift).

Remember that the same is true with the 200/300 series wings. (hint: aft

CG wallow may be reduced by taking a bit of reflex out of the

wing). Remember also that slow speed operation with flaps

fully reflexed requires a high AOA to compensate for the reduction in

lift from the reflex. Be careful out

there.

Max lift, min drag

at 70-100 KIAS is with the flaps at TO position (about +10 degrees

down from full reflex). After about +17 degrees down from full

reflex, the flaps seem to merely add drag that is useful in higher than 3

degree descent angles (preservation of kinetic energy) - keeping the

speed controlled (below 100 KIAS) at low power settings and also

keeping the nose low.

Maybe next time I

will record AOA digital display data in some of these

configurations.

Note 1: In an Air

Venture x-ctry race, KARR was a turning checkpoint that required I descend

over the monitor. In that descent I ran through a mass of little

black bugs (so did others) and my return to level flight as the same race

power resulted in speeds 6-7 KIAS less than before the encounter.

Later, I noted that the splattered bugs were very close together (less than

a 1/4") and had completely messed up the laminar flow at the leading edge of

the wings. Slow downs have also occurred in flight through

rain.

Note 2: Certain

320/360 racers experimented with more reflex with the conclusion that there

was no significant improvement in speed.

=

Gap%20Seal%20stuff.JPG

Gap%20seal%20aileron.JPG

|

|