|

|

Scott,

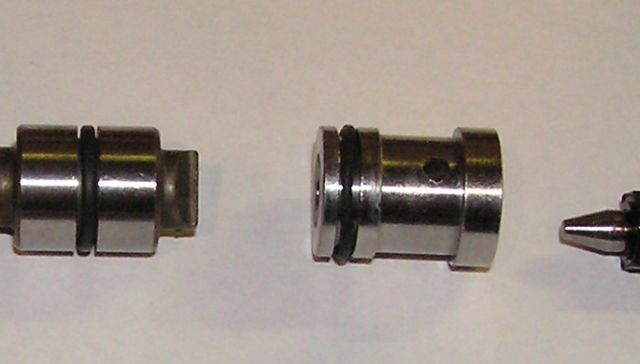

Tough to tell from the picture but, because the seat is static it is

unlikely that the O-ring is "worn". It does look like the O-ring was

"bitten" during installation. Part of the O-ring was sheared off when

the seat was pushed past the step in the bore. This can be avoided by

inspecting the bore for burrs (and removing them), using an assembly

lubricant (like Vaseline) and carefully assembling the parts.

I am assuming that the other difference with the symmetrical shuttle is

an absence of a central vent port. Without the port the system would be

slow to self bleed any air in the circuit. The pumps are valved such

that there is no circulation through the reservoir. You could loop the

system with a line and remove the reservoir without affecting flow.

Reservoir flow only occurs with tidal flow due to cylinder rod volume,

fluid / air compression and system bulk modulus.

This "recirculating" design means that any system contamination is

trapped in the circuit without much chance to get into the reservoir.

Changing the fluid does nothing to remove contamination, moisture or

debris from the circuit. Hydraulic maintenance should therefore involve

flushing the system by disconnecting lines, exercising the cylinders

and running the pump.

Internal port to port leaks are most commonly caused by contamination

in the system. Metal chips, moisture, sanding dust, dirt etc. all spell

death for the system. If contamination gets to the pump it turns the

pump into a contamination generator. A tight, leak free system will

only stay that way if it is very clean. I used to instruct the

technicians that were assembling the servo hydraulic tele-manipulators

that I designed that the system would tolerate contamination as well as

their eyes do. We had 3 micron filters in the supply line and even with

that the servo valves would "silt up" during fixed flow tests.

Regards

Brent Regan

DBF093C3-5EC5-4AF2-BF5B-2C6567DF8158

|

|