Jury Blames Textron Lycoming for Airplane Engine Failures

Orders Company to Pay $96 Million

A jury in Grimes County, Texas has found

Textron Lycoming liable for fraud, and ordered the company to pay approximately

$96 million to Navasota, Texas-based Interstate Southwest Ltd. The verdict came

Tuesday following seven weeks of trial in State District Judge Jerry Sandel's

278th Judicial District Court in Anderson, TX.

A jury in Grimes County, Texas has found

Textron Lycoming liable for fraud, and ordered the company to pay approximately

$96 million to Navasota, Texas-based Interstate Southwest Ltd. The verdict came

Tuesday following seven weeks of trial in State District Judge Jerry Sandel's

278th Judicial District Court in Anderson, TX.

The jury's award includes $9,725,650 in actual damages and another

$86,394,763 in punitive damages. In addition, the verdict effectively precludes

Lycoming from pursuing a $173 million indemnity claim against Interstate, which

it had previously filed in a Pennsylvania court.

"This is a total victory for our side," says attorney Marty Rose, who

represents Interstate Southwest. "Between the verdict and its impact on the

indemnity claim -– we couldn't have hoped for a better result."

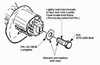

The case revolves around a number of small airplane engine failures that

occurred when the airplanes' crankshafts broke in flight. Between 2000 and 2002,

there were 24 failures and 12 deaths in Cessnas, Pipers and other airplanes with

Lycoming aircraft engines. Interstate Southwest supplied Lycoming with the

crankshaft forgings for those engines.

Following the failures, Lycoming launched an investigation aimed at

determining the cause. Its conclusion was that Interstate Southwest had

overheated the forgings, weakening the steel.

But attorneys for Interstate, Rose and Hal Walker, found a different cause.

Their experts were able to determine that Lycoming's design for the crankshafts,

which dates back to smaller, lower horsepower engines built 40 years ago, was

inadequate for the larger, higher horsepower engines that failed.

They also found that by adding Vanadium to the steel -– something Lycoming

decided to do just before the failures began -– the company further limited the

amount of stress the crankshafts could withstand. Lycoming had added Vanadium to

make the steel harder and reduce the number of machining operations, ultimately

saving the company money.

Ultimately, jurors agreed with lawyers for Interstate, and found that even

Lycoming's investigation of the crankshaft failures was fraudulent.

"The jurors found the combination of poor design and Vanadium pushed these

crankshafts beyond their limits," says Hal Walker. "That's why these planes

crashed, and not, as Lycoming claimed, because Interstate overheated the

forgings."