| Hi people

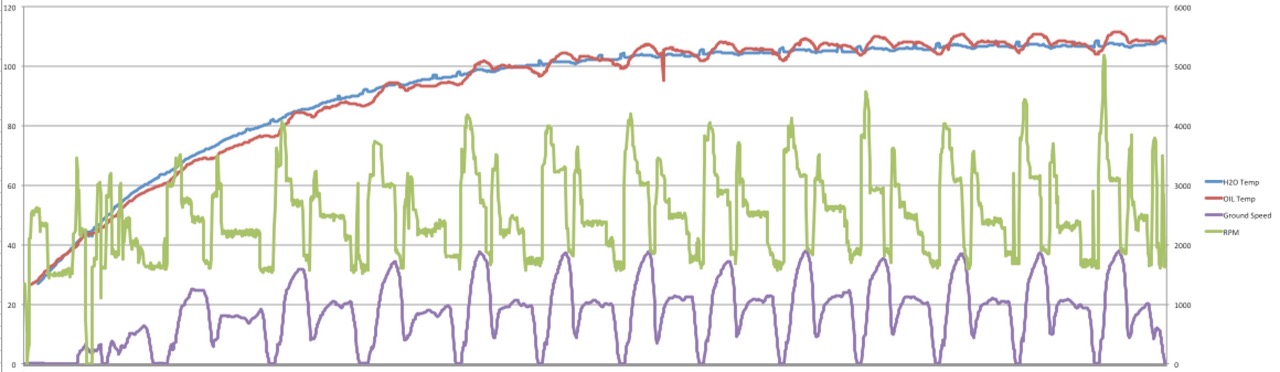

I know how much I have appreciated data over the years so for those interested here is some more. Having looked at last weeks test data and the temps looking like they were close to stabilised after reaching around 212F I thought I would risk it and see what the temps did get to. The temp senders are calibrated accurately up to boiling point (within <1F at 212F) but I’m not sure how accurate they are up at 225F. The graph below is 43minutes of repeatedly (12 times) taxing and then running down our ~1000yard strip at between ~20-37knots The OAT was 74-77F during this test. Renesis 4 port RD1C EC3 EM3 Elect Adj Prop Water cooler is 540in3 (custom dual pass) with inlet of 20in2 Oil Cooler is 193in3 (mazda rx7 turbo) with inlet of 7.5in2

I’m wondering what a 30row oil cooler like Tracy uses might do to both the oil and water temps. We will press on and hopefully flight test it as soon as we have it licensed.

Cheers

Steve Izett

Test Data 23 March 2018.jpeg

|