|

|

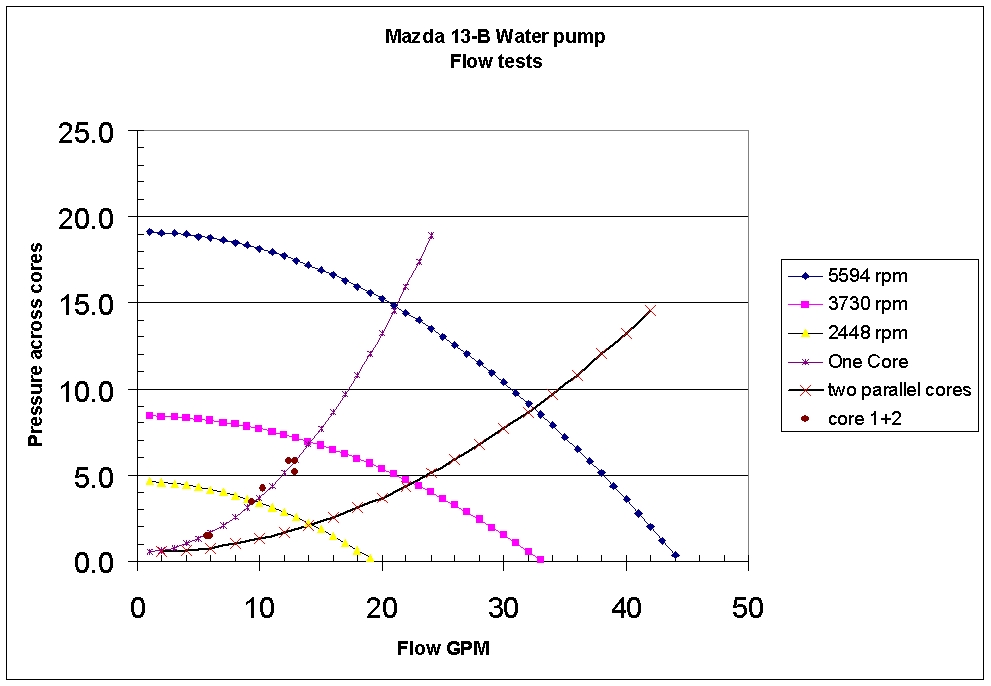

I set up my evaporator cores, hooked them to a garden hose, and did flow

measurements and pressure measurement tests on them, and have overlaid the

pressure rise with flow rate across the core onto the pump pressure curves

that I had previously published. These are shown in the attached figure

"Pump_curve_core_data_clr.jpg".

Some items to take note of on the chart.

1. At full tilt - 5594 rpm, the pump which can deliver 44 gallons per minute

at zero head, can force only ~20 GPM through a single core, and ~31.5 GPM

through two cores in parallel.

2. I have plotted the actual data points taken on the chart. They are on the

"One Core" line, and I was restricted in how much water I could force

through the core by the capacity of the water line in my hanger, and the

length of hose leading to the core. The curves are then, obviously an

extrapolation, using the fact that the pressure drop is expected to be

proportional to the velocity (flow-rate) squared. The data points are a

combination of the results for the two separate cores, combined for the data

fitting.

3. At lower RPM's the flow is reduced dramatically, and these curves make me

question the use of the "under-drive" pulley on the engine, to 'slow down

the water pump'.

4. I did not have an ammeter to measure the current into the motor, but the

1-hp motor did not have any problem driving the pump at ~5600 rpm.

5. I would not advocate having the radiator cap on the pump outlet side, the

pressure that the cap would see would be the system pressure + pump

pressure, so it would be easy to create a condition where the radiator cap

could be overcome and fluid vented. The more I think about it the better I

like Ian's & Lynn's approach of using a pressurized bottle with a

head-space.

6. These curves show the advantage of having the cores in parallel, even

though I know of a good working example of cores in series (Ed Anderson's).

I suspect that Ed's use of AN-16 fittings has contributed to a lower

entrance and exit losses than I am experiencing (basically transitioning

from 1-3/8 to 3/4").

Comments are welcome.

Bill Schertz

KIS Cruiser #4045

Pump_curve_core_data_clr.jpg

|

|