|

|

Sorry about the previous post...brain fart on my

part...I had the A/C mount pad and just had to measure

the depth of the holes, 13mm for 3,4, and 5; 23mm for

1 and 2. So, the offset is 10mm...

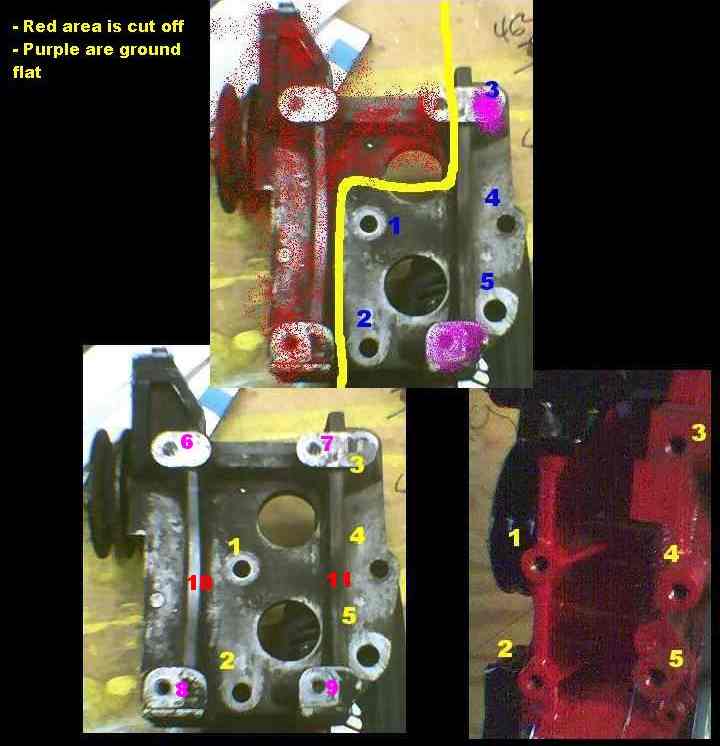

But, this got me thinking, cut a little here, grind a

little there. Then I have a nice flat starting point

for the alternator mount and engine mount.

In the attached photo there are three pictures put

together, the lower right is the engine block, lower

left is the vanilla AC mount pad, and the top one is

what I am thinking about doing to the mount pad.

However, before going on grinding and cutting binge, I

was thinking on how to use the stock pad to mount the

alternator. Unfortunately, the mazda alternator mount

is exactly the width of the cast stiffners 10 and 11.

Or why waste the energy cobbling something together

based on the AC pad, just use a few pieces of flat

stock to build out 1 and 2 to be level with 3,4, and

5. Then move forward with fabricating a single piece

engine mount point and alternator bracket.

I am guessing this is not breaking new ground, thus

what are others doing for an alternator bracket and/or

engine mount point in this area?

Thanx...

-Scott

=====

Thank You.

Regards,

Scott Stout

http://home.att.net/~the_stouts_zenith_801

__________________________________

Do you Yahoo!?

Yahoo! Hotjobs: Enter the "Signing Bonus" Sweepstakes

http://hotjobs.sweepstakes.yahoo.com/signingbonus

use_of_ac_mount_pad_s.jpg

|

|