|

|

Joe Hull wrote:

It was bugging me that I couldn’t remember the reference to the reverse scoop – so here’s the link – it was Dick Rutan:

http://www.ez.org/cp47-p11.htm

Essentially put the reverse scoop on the top of the wing all the way ahead of the oil cooler for best cooling.

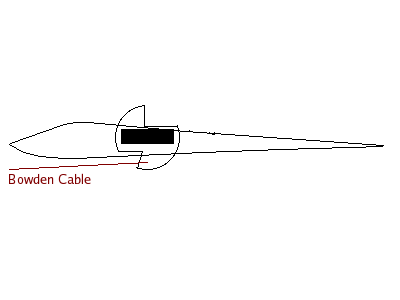

I looked at the drawing and thought that exposing the oil cooler like that would be very dangerous. You need some way to keep kids at the flyins from seeing if they can "hit the basket". I imagined the design concept pasted below. Try very hard to imagine that it's a wing crossection with an embedded oil cooler (the black box). The circular thingy would be a rotating drum, with slices taken off of two sides. The drum would rotate, controlled with a bowden cable, to open and close both the entrance and exit simultaneously. A broken cable would have the drum forced open for full cooling. Works as a flap and protects the cooler on the ground. Proper dimensioning left as an exercise for the reader.

Kelly is correct concerning my project, except that my intakes are not flush. I could possibly get away with flush intakes, but it is easier to cut back than it is to add so I let it drop out the bottom a short bit. My shark gill louvers have turned out really nice, but need a little more cosmetic attention. My biggest concern was filling the fuselage with water when the airplane is on the ramp in the rain as the exits are on top. I've got to add a drain hole on the bottom for blowing rain, but I believe I'll be keeping 95% of the water out.

Having the oil cooler in the strake is offering another benefit. I'm adding a door to the center of the cooler's exit duct that hinges into and out of the duct from the side. This door cuts the cooler neatly in half. A 1.75" hose exits from the intake duct in front of the cooler, and another exits from behind the cooler but in front of the door. A 1.75" hose will exit the air from the cockpit back at the wheel well portion of the duct. Normal operation is to have the cooler door wide open and take cabin cooling air from in front of the oil cooler. Cabin air flow will be set by the pressure differential across the cooler core. When it's really cold, and I need cockpit heat (but not so much oil cooling), I close the door and cabin cooling vent, while opening the cabin heat vents. Closing the door will increase the static pressure at the cabin heating port on the cooler exit duct, commissurate with the pressure on the face of the cooler. The air still exits out the back. Basically, by putting the oil cooler in the strake, I've been able to get cabin heat and a way to reduce cooling drag in one mechanism that is much lighter than other solutions (no extra fans, heat exchangers or muffler heat muffs) For me, the only extra complexity in construction was a piece of round foam taped to the side of my oil cooler mold. The only question is will it work.

--

,|"|"|, Ernest Christley |

----===<{{(oQo)}}>===---- Dyke Delta Builder |

o| d |o http://ernest.isa-geek.org |

drumflaps.png

|

|