|

|

Dave,

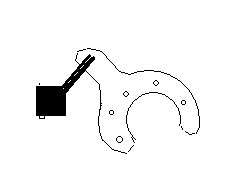

Buly's looks like a fine solution. I used 1/8 steel plate cut in a horseshoe and bolted under 4 or 5 of the small bolts on the end of the redrive. (I checked with Tracy to be sure this is ok). The brushes are mounted at the end of a short threaded rod. This way there's not as much length for vibration. Less moving parts. :) I don't have a picture, but here's a drawing.

One thought to keep in mind. A Hershey kiss spinner looks good, covers the motor and is supposed to help significantly with drag & cooling. The spinner mount plate MUST be AL, not fiberglass, and goes forward of the forward knurled pressure plate. Removing the spinner to check torque can be a pain, so you might want to leave it off until the torque settles - 5 - 10 hours. Here's the main point - the hershey kiss spinner is usually fitted with a flow-guide that helps the air out of the cowl. Getting the brush mount UNDER the flow guide is going to be a challenge, but is probably worth doing. If you can engineer this please make one for me. :)

Regards,

John

77.1 hours and still hmmmin

David Staten wrote:

I am posting this to both groups.. rotary and Canard.. in hopes of getting some good ideas..

I will be mounting a Ivo Magnum on the back of a rotary powered velocity.. I've heard the horror stories with the horizontally opposed engines and IVO's but will give it a shot on a smoother running engine.. The inflight adjustable propellors have a reversible motor in the hub, and its power is provided to the prop by a graphite two conductor brush assembly in a plastic housing.

What I am having difficulty in doing is devising a sturdy enough brush mounting arrangement. 1st arrangement (meant for ground use ONLY consists of some home depot aluminum angle, threaded rod and a few nuts and locknuts.. I tried building a 2nd arrangement tonight out of 26 ga galvanized sheet steel with stiffeners built into two opposing layers (back to back). In the absense of workable feedback, 3rd arrangement will be out of 16 ga sheet steel.. to try and develop rigidity, and will have it form an L or J channel with a horseshoe cutout on the long side to straddle the propshaft and engage as many bolts on the PRSU bearing retainer hub as possible. Currently all my mounting schemes involve the bearing retainer ring mounting bolts on my redrive.

I have a RD-1B redrive from real world solutions as the most likely anchoring point.. just want to get ideas (and pictures) from those who have actually made this work.

Dave

-- Homepage: http://www.flyrotary.com/

Archive and UnSub: http://mail.lancaironline.net/lists/flyrotary/

brushes.jpg

|

|